The industrial sector has seen a transformation because of CNC (Computer Numerical Control) machining, which provides an accurate, economical, and efficient way to produce complex parts and components. Custom CNC machining services can change everything, whether you are operating a large company or a small corporation. It is a vital tool for companies of all sizes because of its many advantages. Let's assess how companies can save expenses, improve manufacturing efficiency, and produce high-quality goods with bespoke CNC machining.

Precision and Accuracy

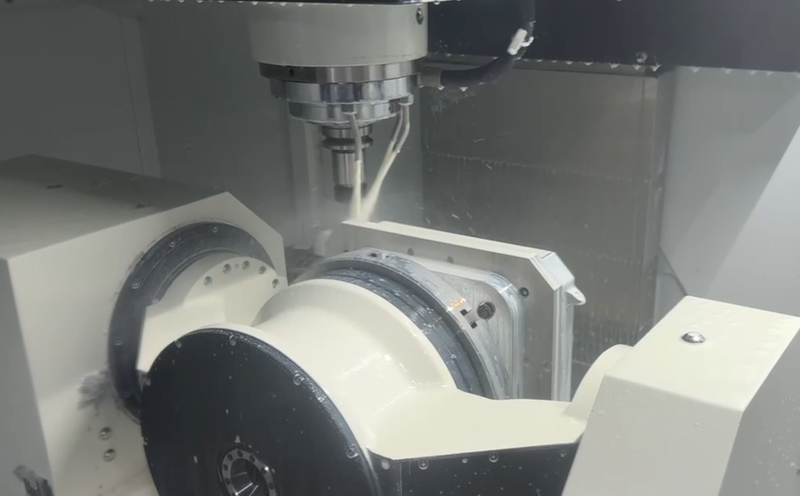

The accuracy of CNC machining is one of its main advantages. CNC machines function with great degrees of accuracy when compared to conventional production techniques. Therefore, CNC machining is perfect for sectors like aerospace, automotive, and medical device manufacture that need precise tolerances. CNC machining ensures uniform quality and precise dimensions for every component, regardless of how many unique parts a small business needs or how many identical components a large company needs.

Cost Efficiency and Reduced Waste

Cutting production costs is a top concern for businesses of all sizes. CNC machining is very effective and wastes very little material when compared to other conventional techniques. The sophisticated technology of CNC machining maximizes the usage of raw resources by enabling precise cuts and reductions. Moreover, CNC machining produces fewer mistakes and requires fewer labor hours, which reduces manufacturing costs and speeds up turnaround times. This is especially crucial for small businesses looking to maintain their competitiveness while reducing overhead.

Flexibility in Design and Prototyping

Businesses may now build sophisticated and complicated designs that would be impossible or difficult to accomplish with old methods after the introduction of custom CNC machining. This flexibility is especially helpful to small firms since it allows them to rapidly prototype, test, and improve their ideas before going into mass production. Metals, polymers, and composites are just a few of the materials that CNC machining can work with. Businesses can produce customized parts for a range of uses, including consumer electronics and automobile components with this flexibility.

The capacity of large businesses to swiftly scale production and iterate designs results in a quicker time to market for new products, which is essential in sectors where innovation is essential.

Scalability for Different Business Sizes

Businesses of all sizes benefit from the scalability that CNC machining provides. While larger organizations can use CNC services to manufacture huge volumes of parts with great consistency, small businesses can employ CNC machining for one-off custom items or small-volume runs without incurring hefty setup costs. CNC machining enables firms that may expand over time to scale their operations with ease, whether they are manufacturing hundreds or thousands of pieces. Moreover, bespoke CNC machining may be modified as the company expands and its product line diversifies because of its scalability.

Long-Term Durability and Reliability

Both small and large enterprises need the durability and dependability that CNC machining offers. CNC-machine-produced parts are made to meet high standards and are resistant to harsh use in a variety of industries. CNC machining ensures that the finished product is robust and long-lasting, whether it is being used to produce tools, prototypes, or mechanical parts.

China Plastic Mold: An Affordable and Reliable Option for Custom Parts

Affordable China plastic molding is becoming a preferable choice when it comes to bespoke CNC machining for plastic parts. A lot of businesses, big and small, rely on China plastic mold suppliers because of their experience and affordable options. China plastic mold industry offers modern CNC machining services, which can create complex, long-lasting plastic parts at affordable costs.

Custom CNC machining is a useful tool for businesses of all sizes. CNC machining can help businesses remain competitive in a fast-paced market by providing precision, cost-effectiveness, design flexibility, scalability, and durability. Moreover, collaborating with competent and reasonably priced plastic mold manufacturers in China offers a convenient way to produce customized parts. Custom CNC machining may help you produce high-quality outputs while reducing costs and increasing overall productivity, regardless of your business size.