Rapid prototyping services are critical in product design, allowing businesses to quickly turn ideas into functional prototypes for faster testing and iteration. Businesses are under pressure to create novel products fast while lowering expenses and risks in the fast-paced market of today. Rapid prototyping has become a revolutionary method that changes the way ideas become products. Before investing in costly production runs, companies can test, improve, and perfect their designs by developing functional models early in the development process. Let's examine five important ways that rapid prototyping services push product design innovation.

Key Benefits of Rapid Prototyping Services

Faster Design Iterations

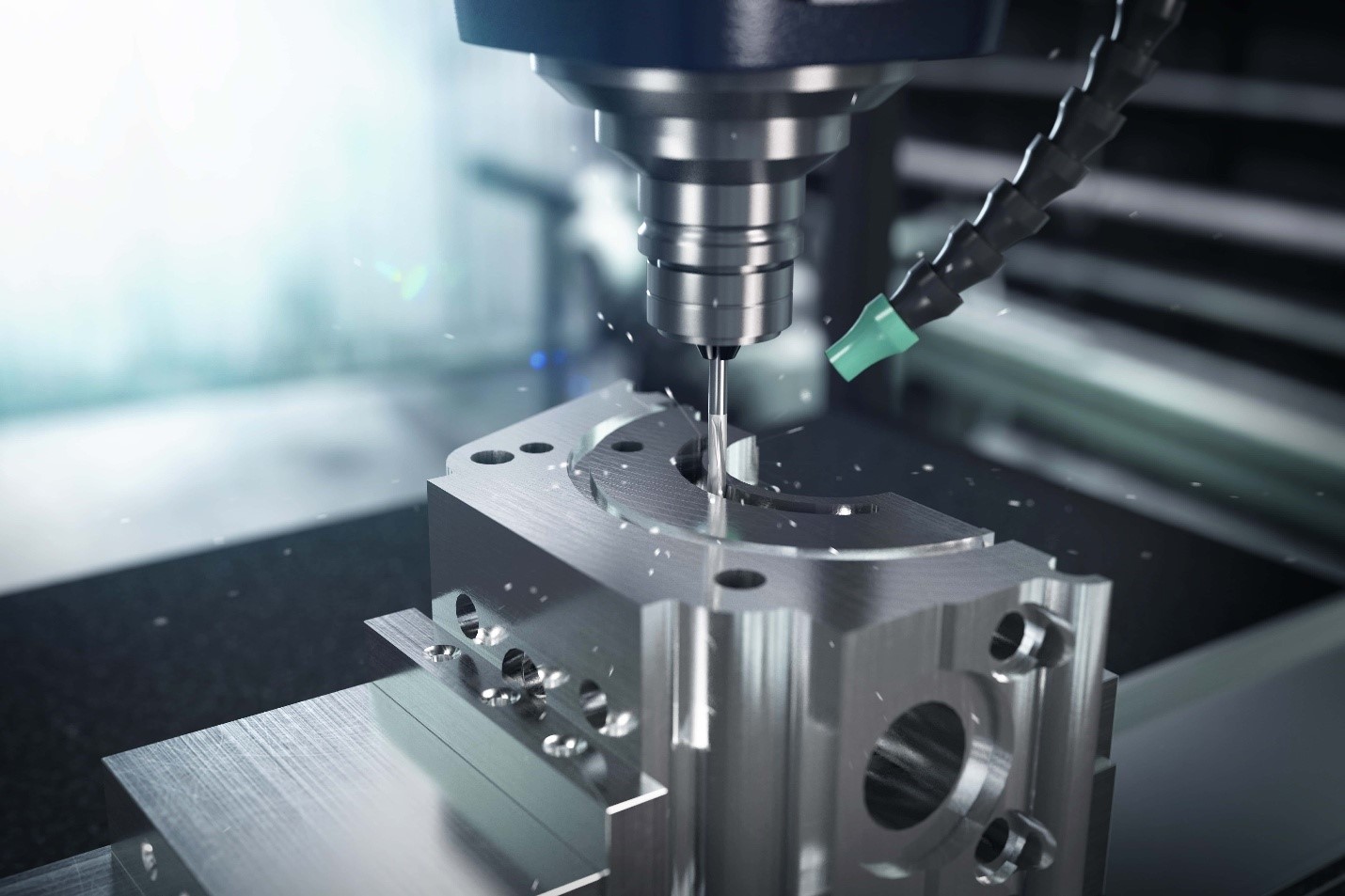

The time it takes from concept to finished product is significantly shortened by rapid prototyping. Today's cutting-edge technologies, such as 3D printing, CNC machining, and injection molding, can produce working prototypes in days or even hours, whereas traditional prototyping methods frequently take weeks or months to produce a single iteration. Because of this speed, design teams can test several iterations quickly, find errors, and make changes without having to wait a long time.

Cost-Effective Risk Management

It can be extremely costly to find design flaws at a late stage of development. Rapid prototyping moves the validation process to the early phases when it is much less expensive to implement changes. Businesses can prevent expensive rework and retooling costs by detecting and resolving problems prior to tooling and production setup. This method minimizes material waste because designs are improved before mass production starts.

Enhanced Collaboration and Communication

Physical prototypes facilitate communication between various stakeholders who may have different interpretations of digital models or 2D drawings. By interacting with the same tangible object, engineers, designers, marketing teams, and executives can all provide more insightful feedback and have more fruitful conversations. Instead of using abstract ideas, clients and end users can offer feedback based on their real interactions with prototypes.

Customization and Personalization Capabilities

Modern consumers increasingly expect products tailored to their specific needs. Without the high expenses associated with conventional manufacturing techniques, rapid prototyping services allow for the effective testing of customization options. Small batches of specialized designs can be quickly produced by businesses to gauge market response prior to expanding production. This feature is especially useful in consumer goods, where customization leads to premium pricing opportunities, and in medical devices, where patient-specific solutions enhance results.

Accelerated Time-to-Market

Businesses can launch products weeks or months ahead of competitors who use traditional methods by accelerating the design validation process. This benefit translates straight into business value, enabling firms to take advantage of market gaps before they fade and to take the lead in new product categories. A quicker time to market also means an earlier return on development investments and faster revenue generation.

Final Thoughts

Rapid prototyping services have fundamentally transformed the product development landscape by enabling faster iteration and accelerating time-to-market. We can expect even more advanced prototyping tooling options that further streamline development cycles and increase creative possibilities as technology advances. Rapid prototyping is not only beneficial for businesses that want to stay ahead of the competition, but it is also necessary for them to survive in a market that is driven by innovation.

FAQs

Which technologies are often used in rapid prototyping?

The primary technologies are rapid injection molding, vacuum casting, CNC machining, and 3D printing (additive and subtractive manufacturing).

Is it possible to conduct functional testing with rapid prototypes?

Yes, models with features that closely resemble those of production materials can be created using contemporary prototyping techniques, enabling useful functional and performance testing.

How can I decide between the various approaches to rapid prototyping?

When choosing the right method, take into account your needs for material properties, dimensional accuracy, surface finish, production quantity, turnaround time, and budget.

Are rapid prototypes suitable for consumer testing?

Although durability and appearance may differ slightly from final production versions, many contemporary prototypes are sturdy enough for limited consumer testing.

Ready to accelerate your product design with rapid prototyping services? Contact UIDEA today for a free consultation and to start your project!