China is now at the forefront of manufacturing innovation, and its credit goes to the quick development of 3D printing technology. The global manufacturing powerhouse’s adoption of additive manufacturing has revolutionized numerous sectors. Chinese businesses are adopting 3D printing to lower prices, increase manufacturing efficiency, and produce intricate parts that were previously unattainable through conventional methods.

Aerospace Component Manufacturing

Aircraft firms have used 3D printing in China to create components that are both lightweight and robust. Selective laser melting (SLM) technology is being used by businesses to produce complicated interior structures and sophisticated engine parts. This resulted in a 30% weight reduction in certain components without compromising structural integrity, which has increased aviation engines' fuel efficiency.

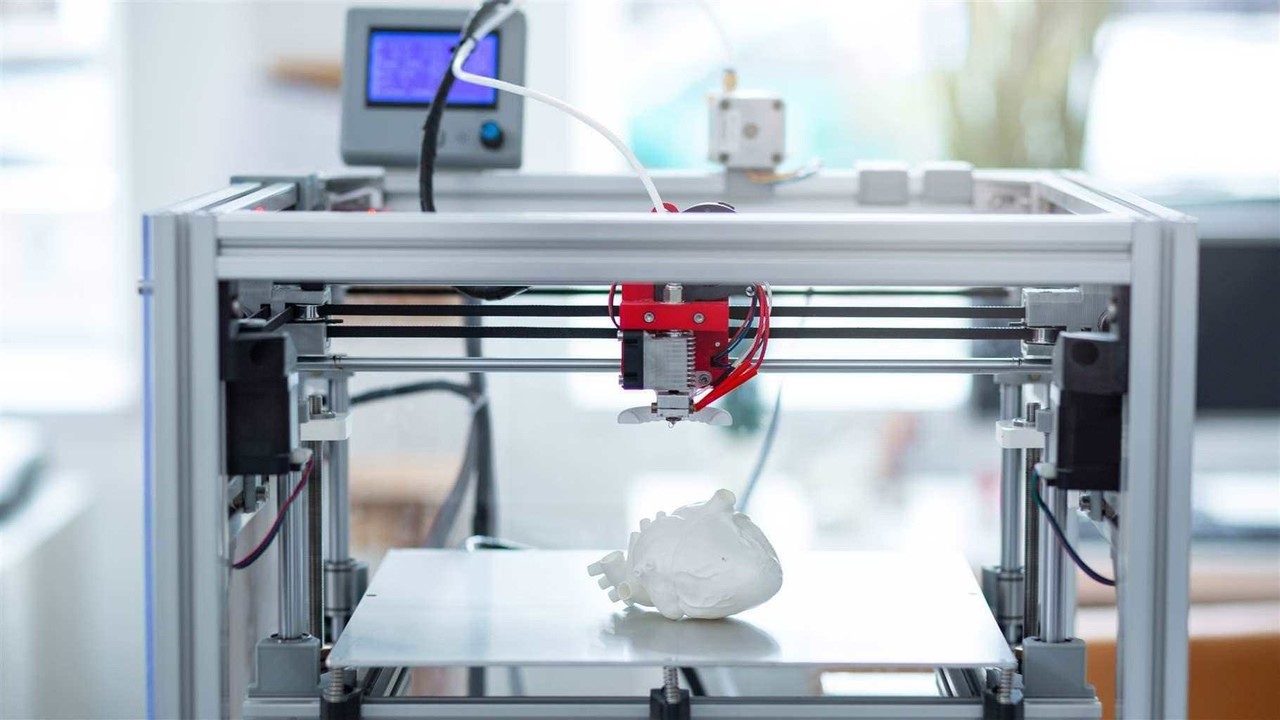

Medical Device Customization

3D-printed implants and medical equipment have revolutionized the healthcare industry. Biocompatible materials are being used by Chinese hospitals and medical device manufacturers to create prostheses, surgical guides, and implants tailored to each patient. Many medical technology businesses have effectively used 3D printing to produce customized orthopedic implants, increasing patient outcomes and cutting down on surgery time by 40%.

Rapid Prototyping in Consumer Electronics

The technology hub of Shenzhen is home to major electronics manufacturers who have included 3D printing in their product development cycles. Businesses can now create working prototypes in a matter of hours rather than weeks, which speeds up iterations and shortens the time to market. In the design of wearables, smartphones, and Internet of Things devices, where several design iterations are essential for product improvement, this has had a particularly major impact.

Automotive Tooling Innovation

3D printing has been adopted by the automotive sector for both production and prototyping uses. One significant development involves the use of 3D printing by manufacturers to create intricate mold inserts with conformal cooling channels for automotive injection mold components. This invention has greatly increased mold life spans, decreased cooling times by up to 40%, and significantly enhanced part quality.

Construction and Architecture

Chinese construction companies are pioneering large-scale 3D printing applications in building construction. Businesses can use specialty concrete combinations to effectively print complete structures. When compared to conventional approaches, this technology has reduced construction waste by 60%, labor expenses by 50%, and building time by 70%.

Bottom Line

China has shown its dedication to preserving its position as the world's manufacturing leader by implementing 3D printing technology across a range of industrial sectors. In addition to lowering prices and increasing production efficiency, technology has made it possible to create innovative products that were previously unfeasible to produce. It is expected that the uses of 3D printing in China will grow further as businesses here continue to make investments in R&D, potentially transforming other sectors and production methods. China's manufacturing capabilities have advanced significantly as a result of this technological advancement, which has raised the bar for industrial production worldwide.