Precision CNC Machining Services

Uidea Rapid Prototype is a leader in CNC machining services, equipped with advanced CNC machines featuring a maximum machining stroke of 1800×650×600mm. We provide high-quality CNC prototypes and CNC production solutions, specializing in precision CNC machining to meet the most demanding requirements for material properties and tight tolerances.

Our CNC machining services cover a wide range of processes, including CNC milling and CNC turning, enabling the creation of prototypes and production parts with consistent accuracy and cost-effectiveness. From single prototype pieces, low-volume manufacturing and final CNC production, we ensure that every part is crafted with exceptional precision and care.

With our unwavering focus on precision CNC machining, Uidea delivers reliable and innovative solutions, making us the go-to partner for all your CNC prototype and CNC production needs.

As a trusted name in CNC machining China, now, Uidea is becoming more and more focusing in CNC machining high precision parts with tight tolerances.We offers the flexibility to work with various materials, including plastics, metals, and complex geometries such as undercuts and double-bent surfaces. Additionally, we excel in handling specialty materials like titanium, magnesium, and nickel, meeting the unique demands of industries requiring advanced material capabilities.

Materials:

Aluminum: AL6061-T6, AL6063, AL6082, AL7075-T6, AL5052, etc.

Steel: SUS301, SUS304, SUS303, SU316L, SUS440C, S355ML, S420ML, P20, SKD11, SKD61, SKH9, SKH51, S45C, etc.

Other Metal: Titanium, Brass, Copper, Magnesium, Nickel etc.

Plastic: ABS, PP, PC, Nylon, PMMA, PEEK, Nylon+ 30%GF, Acetal (POM), PE, UHMWPE, PET, PTFE (Teflon), etc.

Surface Finishes:

As machined (around Ra3.2μm), Smooth (around Ra1.6μm), Polishing (around Ra0.8μm), Mirror Polishing (aroundRa0.5μm),

Painting, Black Oxide, Beadblasting, Power Coating, Brushing, Type II Anodizing, Type III Anodizing (Hard), Heat Treatment, PVD Coating, Plating, Silk Screen, Pad Printing, etc.

|

CNC Machining Auminum Part |

CNC Machining Case Study |

CNC Machining Clear Part |

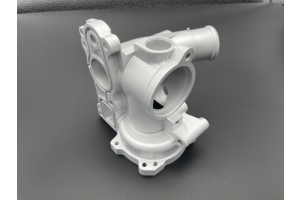

Precision CNC Machined Aluminum Part

Precision CNC Machined Aluminum Part

CNC Machined 17-4PH Stainless Steel Parts for Robotic Arms

CNC Machined 17-4PH Stainless Steel Parts for Robotic Arms

Precision AL7075-T6 Parts for Robotic Arms

Precision AL7075-T6 Parts for Robotic Arms

CNC Machined Aluminum Part with Mirror Polishing & Chrome Plating

CNC Machined Aluminum Part with Mirror Polishing & Chrome Plating

Precision CNC Machined17-4PH Stainless Steel Parts for Robotic Arms

Precision CNC Machined17-4PH Stainless Steel Parts for Robotic Arms

CNC Turned Precision AL7075-T6 Parts

CNC Turned Precision AL7075-T6 Parts

CNC Turned & Milled Precision AL2024 Parts

CNC Turned & Milled Precision AL2024 Parts

Precision CNC Machined AL6061-T6 Parts for Robotic Arms

Precision CNC Machined AL6061-T6 Parts for Robotic Arms

Precision CNC Machined Aluminum 2024-T351 Parts for Robotic Arms

Precision CNC Machined Aluminum 2024-T351 Parts for Robotic Arms

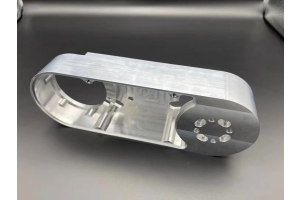

Precision CNC Milled AL6061 Parts

Precision CNC Milled AL6061 Parts

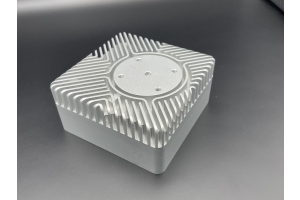

CNC Machined Precise and Complicated Aluminum Product

CNC Machined Precise and Complicated Aluminum Product

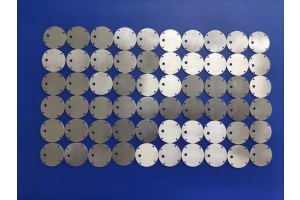

CNC Machining Aluminum Part for Mass Production

CNC Machining Aluminum Part for Mass Production

Precision CNC Machined Aluminum Parts with Matte Anodizing Finish

Precision CNC Machined Aluminum Parts with Matte Anodizing Finish

Precision CNC Machined Stainless Steel Part with Mirror Polishing

Precision CNC Machined Stainless Steel Part with Mirror Polishing

CNC Machined Titanium Alloy Parts

CNC Machined Titanium Alloy Parts

Precision Metal Parts

Precision Metal Parts

CNC Machined High Precision Stainless Steel Parts

CNC Machined High Precision Stainless Steel Parts

Precision AL6061-T6 Parts for Robotic Arms

Precision AL6061-T6 Parts for Robotic Arms

Precision Stainless Steel Part

Precision Stainless Steel Part

CNC Machined Precision Steel Part

CNC Machined Precision Steel Part