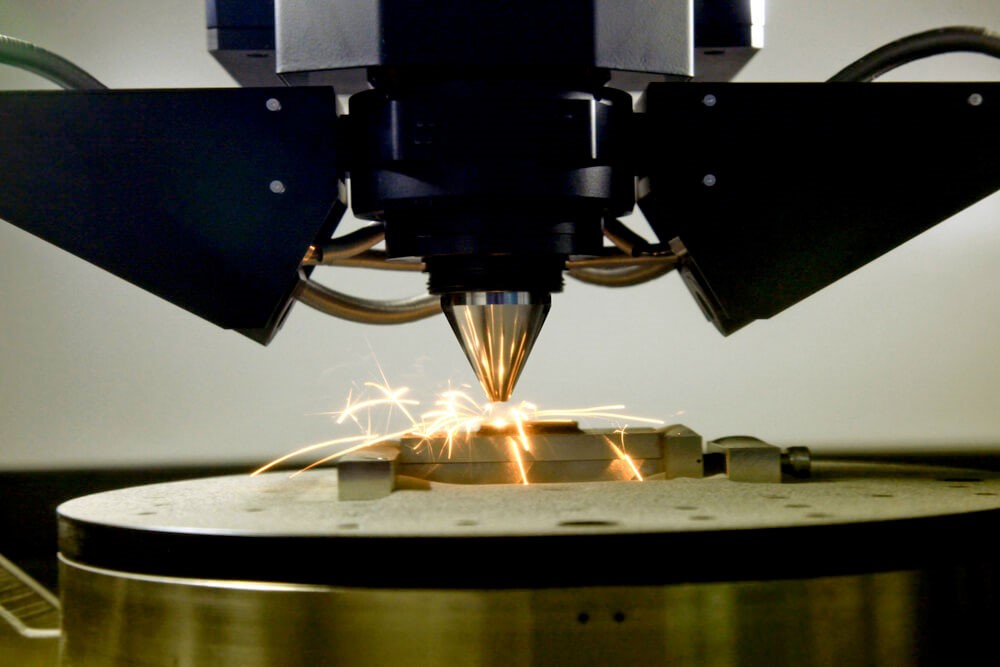

3D printing has completely transformed manufacturing, making it possible to produce prototype tooling and intricate parts at previously unheard-of speeds and accuracy. This cutting-edge technology does, however, provide a unique set of difficulties. In this blog post, we'll look at five typical obstacles to metal 3D printing and how professionals handle them.

Residual Stress and Warping

Handling residual stress is a major problem in 3D printing metal since it can distort or warp objects. This happens as a result of the printing process's quick heating and cooling. In order to reduce thermal gradients, experts optimize printing parameters including laser power and scan speed. They also use sophisticated simulation software to anticipate and correct for possible warping. In order to lessen any remaining strains in the finished product, some manufacturers also apply heat treatments that relieve tension after printing.

Powder Management and Recycling

Fine metal powders, which can be expensive to create and difficult to handle, are necessary for metal 3D printing. For consistent print quality and economical production, efficient powder management is essential. Experts follow strict powder handling procedures to guard against contamination and guarantee worker safety. In order to recycle old powder for use in subsequent prints, they also make use of sophisticated technologies for sieving and filtering powder.

Surface Finish and Post-Processing

To obtain the appropriate surface smoothness and dimensional accuracy, metal 3D-printed components frequently need intensive post-processing. This can complicate things and raise production costs significantly. Experts are creating new printing methods and materials to solve this problem, producing pieces with better surface quality straight out of the printer. In order to effectively improve surface smoothness, they also use sophisticated finishing methods like chemical polishing and shot peening.

Build Chamber Atmosphere Control

Oxygen contamination can cause printed components to oxidize and become porous, which will reduce their mechanical strength. Professionals get around this problem by employing sophisticated gas management systems that keep an inert environment (often nitrogen or argon) during the printing process. Some state-of-the-art devices even have real-time chamber atmosphere monitoring built in, enabling quick modifications to guarantee ideal printing circumstances.

Design Optimization for Additive Manufacturing

Conventional design methods frequently fall short of fully utilizing the special powers of metal 3D printing. This may lead to inefficient use of support structures or subpar part performance. Experts are using design for additive manufacturing (DfAM) concepts to overcome this. By optimizing part topology using cutting-edge software techniques, they may reduce weight without sacrificing strength. This process makes it possible to create lightweight structures and intricate cooling channels for prototype tooling, which would be impossible with conventional manufacturing techniques.

By addressing these issues, professionals are consistently expanding the limits of metal 3D printing's potential. These developments are making metal additive manufacturing a more alluring choice for a variety of industries, from raising part quality to cutting costs and broadening applications in areas like prototype tooling.