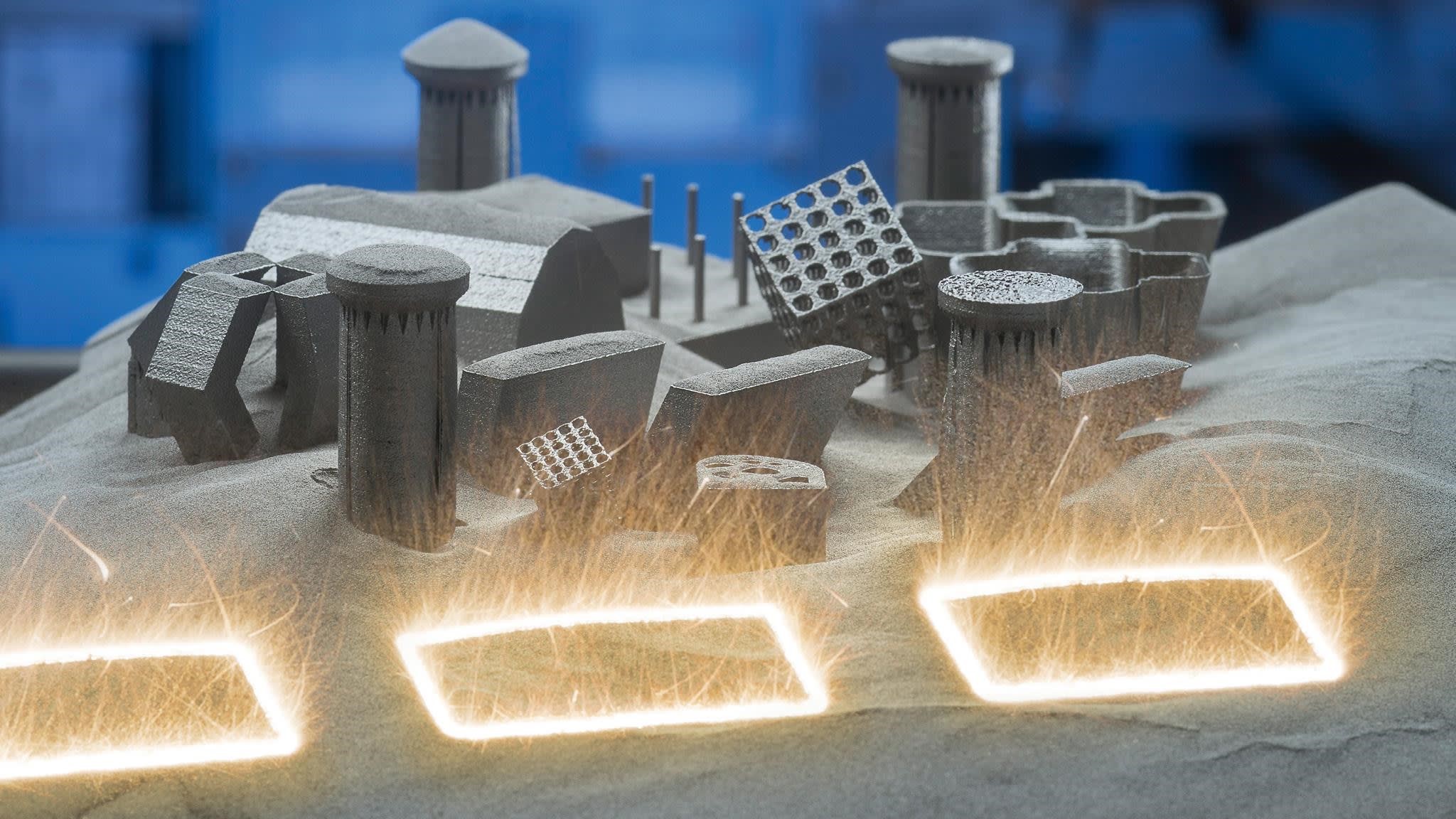

The field of manufacturing has completely changed with the revolutionary technology of Selective Laser Melting (SLM) 3D printing. SLM provides unmatched flexibility and precision by fusing powdered metal into solid shapes using powerful lasers. Here is the list of the top five industries in which SLM 3D printing is used:

Aerospace and Aviation

SLM 3D printing is a perfect fit for the aerospace and aviation sector, which requires parts that are both extremely strong and lightweight. Manufacturers can use SLM to build complex geometries that aren't achievable with conventional techniques. As a result, lighter and more performance-enhancing structural components, such as fuel nozzles and turbine blades, can be produced.

Medical and Dental

SLM 3D printing has made it possible to provide more individualized treatment in the medical and dental sectors. With this technology, dental crowns, prosthetic limbs, and implants can all be made specifically to fit each patient's body. Patients' comfort and effectiveness of medical treatments are enhanced by this degree of personalization. SLM is also utilized to create sophisticated surgical equipment that improves surgical results. The implants are safe and effective for long-term usage since the materials used in SLM are biocompatible.

Automotive Industry

The precision and flexibility offered by SLM 3D printing are highly advantageous to the automotive sector. With this, parts can be prototyped quickly, which expedites the stages of product development that involve design and testing. It allows manufacturers to produce robust, lightweight parts that enhance vehicle performance and fuel economy. When replacement parts for vintage or specialty cars are no longer available, SLM is also used to create custom parts for such vehicles. With SLM 3D printing, automotive businesses can achieve lower manufacturing costs and faster turnaround times.

Tool and Die Making

The capacity to make extremely precise and long-lasting components is essential in the tool and die industry. So SLM 3D printing is excellent at accurately creating intricate tool geometries. This is especially helpful for prototype injection molding since high-quality prototypes need exact molds. SLM makes it possible to produce these molds with fine details and a smooth surface, guaranteeing that the prototypes fulfill the required requirements. This improves the overall efficiency of the manufacturing cycle and cuts down on the time and expense involved in traditional mold-making procedures.

Jewelry and Fashion

Jewelers are able to craft one-of-a-kind pieces with intricate patterns that are challenging to achieve using conventional techniques. SLM's accuracy makes it possible to produce smooth finishes and minute details, both of which are necessary for jewelry of the highest caliber. Designers in the fashion industry also employ SLM to push the creative boundaries with their avant-garde accessories and components. With this technology, designers can quickly realize their ideas through small-batch production and rapid prototyping.

Key Takeaways

SLM 3D printing is transforming a number of industries by making it possible to precisely and effectively produce intricate, superior, and personalized components. The SLM 3D printing’s wide range of applications demonstrates the revolutionary potential of this cutting-edge technology. Its influence on product creation and production processes will only increase as it develops further, offering new opportunities for creativity and innovation in a range of industries.