Prototypes are formed usually because a product can be tested first before a company fabricates it in abundance. The methods used for creating a plastic prototype and mass production of the final product are not the same. It is mainly because the cost, lead time, and flexibility vary greatly in both cases.

In general, plastic products are mass-produced using various molding methods such as injection, rotational, blow molding, and thermoforming. These methods are cost-effective and practical for only high-volume production. However, when you want to create a prototype, the same methods can be highly expensive. Thus, this is where rapid prototyping service comes in.

A rapid prototype service may include different fabrication processes to produce a prototype that can range right from more advanced additive methods to traditional rapid injection molding and CNC plastic machining. In this post, we will walk you through different types of rapid prototyping processes.

Creating Plastic Prototypes Using Rapid Prototyping Service

Different methods can be used for plastic rapid prototyping with the commonalities that all are suitable for low-volume production and all of them can produce parts rapidly. Hence, these methods are typically referred to as rapid prototyping.

Additive Manufacturing

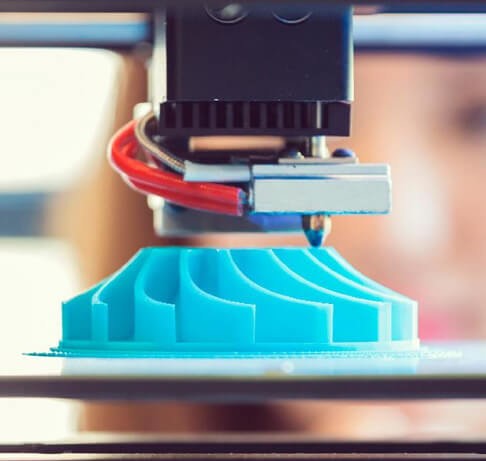

Commonly known as 3D printing, this process forms a part by binding layers of material together into a desired shape and size. It involves designing a CAD file, setting up the machine, and loading up the raw material for prototype creation. The most common methods of 3D printing are Stereolithography (SLA), Selective Laser Sintering (SLS), and Fused Deposition Modeling (FDM). Additive manufacturing is the best option for producing prototypes that have highly complex geometry. Designers typically use this method when they want to get a glimpse of the actual product’s size and shape.

Rapid Injection Molding

This prototyping method is the same as the traditional injection molding with the only difference being that the mold used for injection rapid molding is made at a shorter lead time and a lower cost.

For this method, molds are usually created using less robust material such as aluminum instead of traditional steel. It helps reduce the cost of tooling and enhance the speed of production.

One can choose from a wide range of materials and can achieve a smoother surface finish compared to additive manufacturing. Besides, one can use this method to produce a relatively higher amount of prototypes because it involves the use of a mold.

CNC Machining

This is the most reliable and preferred method for fabricating a prototype that requires higher dimensional accuracy, excellent surface, and shorter lead times. However, it is beneficial for low volume production only. This versatile method can produce complex parts.

At present, various types of plastics can be easily machined. Some examples of machinable plastics include ABS, PC, PP, PP, POM, PMMA, HDPE, Teflon, etc. When creating prototypes for aerospace and high-strength applications, they are usually CNC machined as it allows designers to simulate the actual strength and functionality of a part.

Thus, when you are still at the stage of determining whether a part is robust enough or offers the desired functionality, you should stick to rapid prototyping services china to come up with the desired final product.