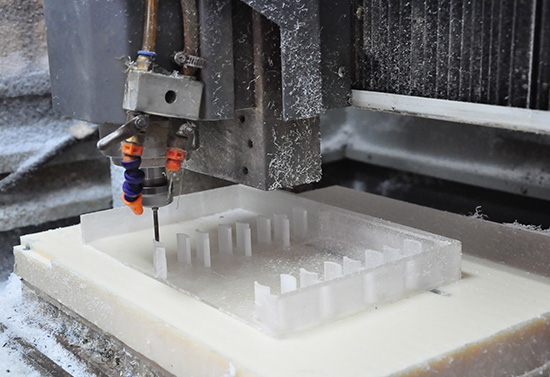

The rapid prototyping process is automating the making of a prototype and it builds a prototype form a 3-D (three-dimensional) CAD model. The rapid prototyping method is capable of making parts with the small internal cavity. The prototyping process is an additive process and it helps in building an object by joining layers of raw materials. The SLA Rapid Prototype is the manufacturing method based on 3D CAD, rapid layer separation, and accumulating principles.

The rapid prototyping process helps to create physical scale models of products for analysis and product tooling through computer-aided design tools. CAD programs have never been cheaper in relative terms. 3D models have never been made so fast and cost-effectively. The 3D printing materials are used to produce prototypes ranging from resins, polymers, and plasters. The best use of 3D printing material for the projects is determined by the key use of 3D printing.

What is the need for rapid prototyping process?

These are the points that will highlight the advantages of rapid prototyping –

There Are New Opportunities for Innovation:

Rapid prototyping is opening up new opportunities for innovation by eliminating the restrictions of conventional prototyping. It requires the production of prototype tooling and physical components to extract tolerances.

The Prototyping Process Helps Saving Time

It is eliminating the time needed to produce molds, patterns and special tools required for conventional modeling. It also reduces the time between initial design and analysis.

The Prototyping Process Helps in Cost Reduction

Rapid prototyping helps the reduction of cost of product development. There is no need for the development of special tools for each new product. The automated prototyping process helps the reduction of staff cost.

The Prototyping Process Lowers the Risk

Rapid prototyping can reduce the risk of costly errors by enabling the detailed physical analysis at an early stage in the development program. The development team is able to identify the design faults quicker to make the modification quickly.

The Process Also Provides Customization Process

This iterative process is easy to incorporate the customer requirements and create customized products. Customization will provide a strong advantage by offering greater choice and flexibility.

What technology should you use for prototyping?

Here Are the Different Types of Rapid Prototyping –

• 3D printing (3DP)

• Ballistic Particle Manufacturing (BPM)

• Directed Light Fabrication (DLF)

• Direct-Shell Production Casting (DSPC)

• Fused Deposition Modeling (FDM)

• Laminated Object Manufacturing (LOM)

• Shape Deposition Manufacturing (SDM) (and Mold SDM)

• Solid Ground Curing (SGC)

• Stereolithography (STL)

• Selective Laser Sintering (SLS)

The rapid prototyping model is used over a range of applications and it helps the manufacturing of production-quality parts in relatively small numbers. The prototyping process starts with the creation of geometrical data using a CAD workstation. The data must represent a valid geometric model for rapid prototyping. The rapid prototyping process produces mockups that deliver the actionable user insights being as efficient as possible.