If you’re a design engineer or product designer, you would be glad to know that vacuum casting is one of the most versatile prototyping methods because of its range of properties and simplified development process. Appearance and properties closely suit the production part that may be produced from high-performance and engineering polymers, such as ABS, polycarbonate, nylon, polypropylene, and elastomers.

A variety of vacuum casting materials showcase designers’ specific requirements for mechanical, physical, and thermal properties which their parts should contain. While we are understanding different types of materials, it is vital to ensure they adhere to certain characteristics or factors.

Materials used in vacuum casting must consist of specific properties and features that include some degree of:

· Physical appearance quality

· Surface finish

· Rigidity

· Flexibility

· Transparency

· Strength

· Hardness

· Temperature resistance

· UV stability

· Color

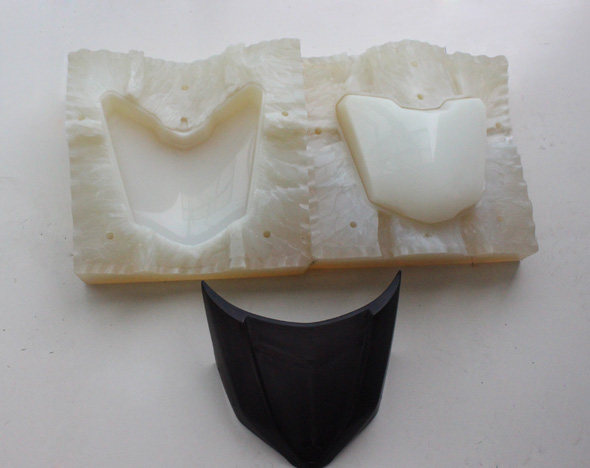

This is casting process uses a vacuum to attract any liquid material into the mold, typically used when air entrapment is a big problem with the mold. It is sometimes called thermoforming because the manufacturing process involves rapid prototyping where plastic sheets are preheated until they become soft and flexible.

Materials for Vacuum Casting and their Properties

Now that we know material choice for vacuum casting needs to adhere to certain characteristics, our next step is to which materials possess such valuable properties.

Vacuum casting makes the best use of polyurethane materials that have thermoplastic properties. What’s more important is such materials accurately reflect properties that are quite similar to elastomer rubber, ABS, and many others.

Here’s the list of vacuum casting materials with useful properties:

· Rubber – Higher flexibility

· Polypropylene and HDPR – High elasticity

· ABS – High rigidity and strength

· Polyamide and glass-filled nylon – High rigidity

· Polycarbonate and PMMA – Shock resistance, high-temperature resistance, and translucence

· Filled ABS – Fire resistance and retardance

Of course, you should definitely consider someone experienced in the prototyping sphere to get genuine advice on which materials are the best fit to achieve the properties you require. If that’s the case with you, feel free to consult Uidea. We will help you with expert advice and support in every scenario of prototyping requirements and projects.