The construction of both structural and external prototypes is critical during the project development stage.

Prototypes are the most visible representations for determining whether the aesthetic and structural design are appropriate. It might identify potential issues early on, serve as an inspection platform for volume production, and efficiently prevent the risk of direct scale manufacturing.

Due to numerous constraints, the majority of prototypes were previously produced by hand. As a result, the prototype's processing-cycle was prolonged. It was also tough to strictly adhere to the structure's dimension specifications.

But because of the rapid advancement and development of technology, the prototyping process now has superior technical support.

The widespread use of CNC machining centers, CNC lathes, CNC milling machines, laser cutting machines, and other post-processing equipment ensures that prototype manufacturing is precise and quick.

Rapid prototyping process solutions

Increasing market competition has made the development of new products a point of contention. Also, the current rapid prototype method in China can significantly enhance the development of new products.

Three primary methods of rapid prototyping:

1. CNC (subtractive manufacturing)

CNC machining has the advantage of correctly reflecting the information on the drawing. It's ideal for prototypes with high technical demands and excellent surface quality.

CNC machining technology has now become an industry in the field of prototype production. It is also the most common form of quick prototyping, which is mentioned in the field of industrial design and mainly relates to CNC machining.

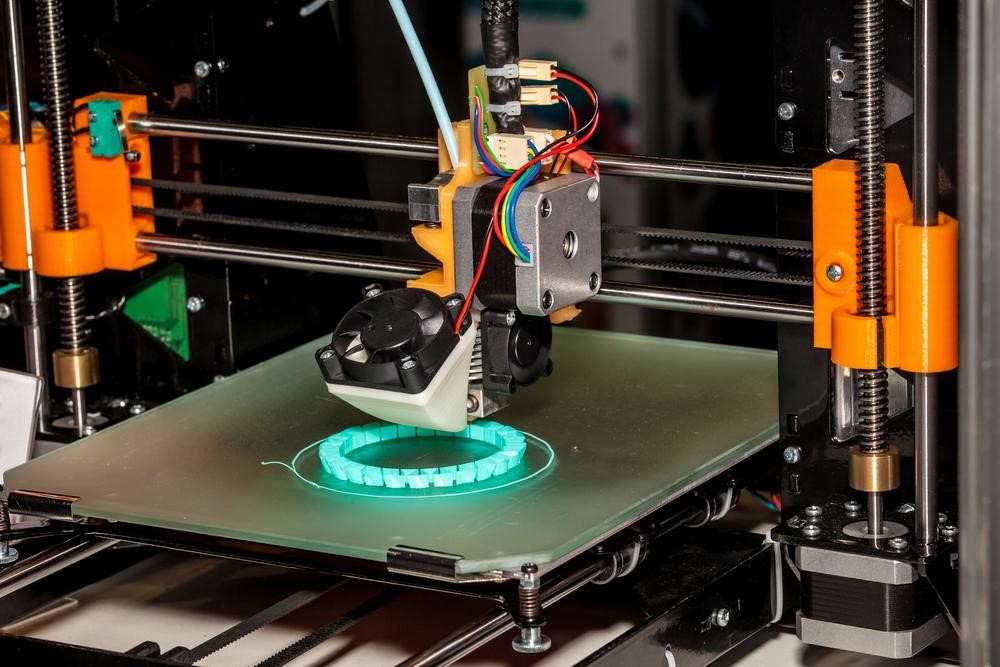

2. 3D Printing (additive manufacturing)

In today's industrial industry, 3D printing is widely employed. Plastics and metals are among the printable materials, but there is always an opportunity for development. On the other hand, this indicates that the 3D printing development trend is positive.

Due to material limitations, 3D printing prototypes constructed of plastic cannot currently withstand high temperatures. They're a touch brittle, and they have other flaws. Also, they are generally appropriate for structure verification.

If the prototype requires a lot of fine-tuned post-processing, another prototyping technique might be a better option.

3. Quick mold Manufacturing

· Vacuum casting is best for trial sample pieces with more intricate structures, consistent wall thickness, and operational needs.

· An injection mold is a tool used to make plastic pieces. It can provide accurate measurements and comprehensive structure to plastic items. Injection molding can be used to produce certain parts in batches.

· Low-pressure injection molding is ideal for producing simple design cover/lid parts, huge thick-walled parts, and components with irregular wall thickness.

Summary

Pre-exploration and communication are vitally important, regardless of which rapid prototype is subsequently used. It is common for the prototype verification phase to be combined with the final volume production process.

More preparation may increase the speed with which the task is completed. Doing good pre-research work during the design development stage will lessen the danger of volume production in the future.