Aluminum extrusion prototyping has emerged as a key technology in modern product development, offering businesses a flexible and effective way to transform ideas into tangible products. Aluminum extrusion has established itself as a standard procedure for design testing and prototyping before mass production in different industries, including electronics, aerospace, automotive, and construction.

We are going to discuss the main benefits of aluminum extrusion prototyping for product development and why engineers, manufacturers, and designers prefer to use it.

Cost-Effectiveness

Using traditional prototyping techniques like casting or machining can be costly, particularly when working with detailed or sophisticated designs. However, aluminum extrusion is a more reasonable option because it streamlines the production process and uses less material. One die can be used to manufacture unique profiles, which further minimizes the requirement for several machining procedures and saves money. Thus, aluminum extrusion prototyping is a great choice for businesses trying to create high-quality prototypes at a reasonable cost.

Design Flexibility

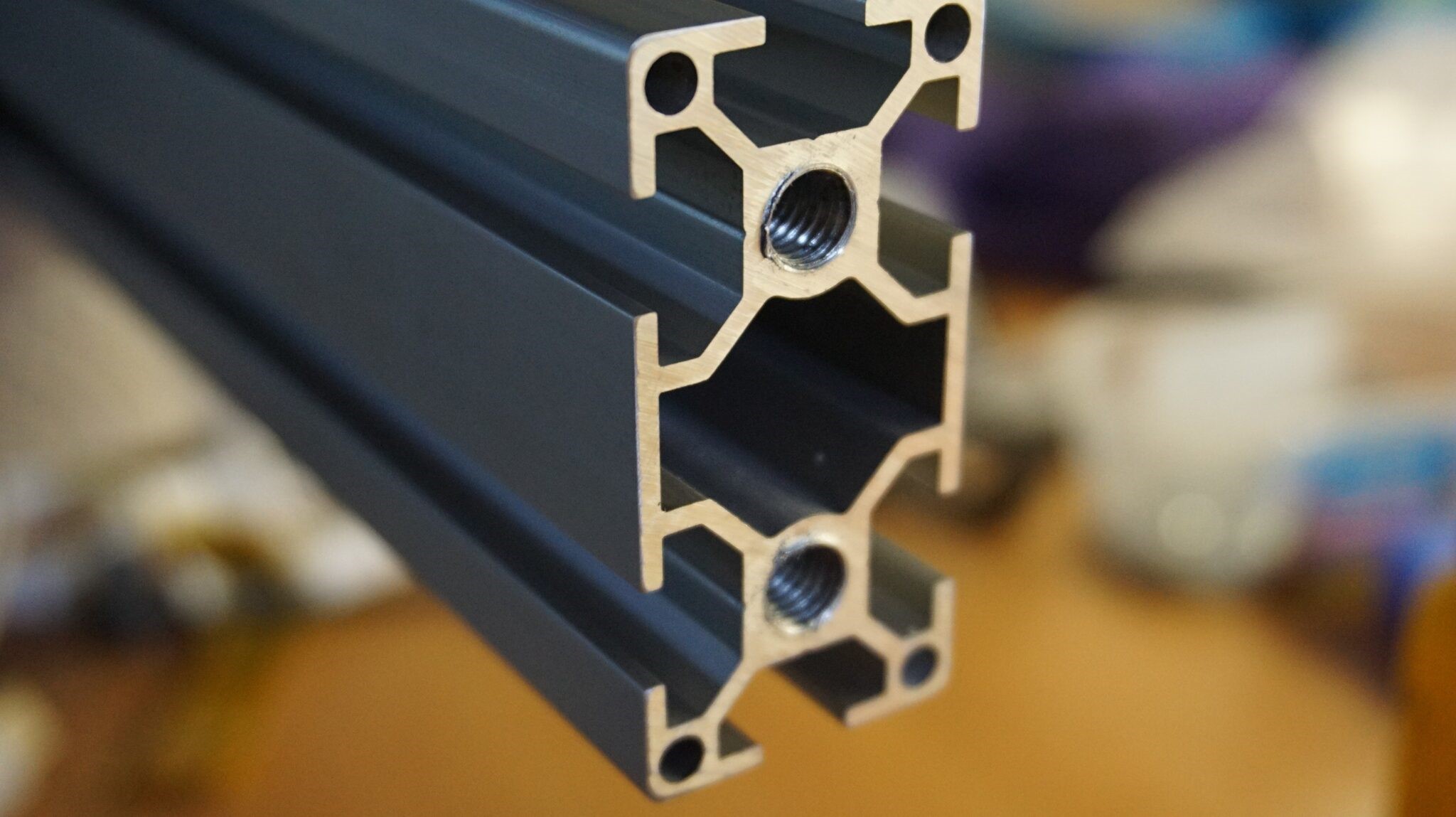

Aluminum extrusion offers exceptional design freedom, which makes it appropriate for a variety of product uses. Complex cross-sectional shapes that would be difficult or impossible to build with conventional production methods can be created using the extrusion process. Designers can test out various setups and improve the functionality, performance, and appearance of their goods utilizing this adaptability. Moreover, different thicknesses, hollows, and multi-void profiles can be accommodated via aluminum extrusion, giving designers more control over the finished product.

Faster Turnaround Times

Speed is crucial in product development, particularly when time-to-market confers a competitive edge. Turnaround times are much lower with aluminum extrusion prototyping than with China plastic mold or CNC machining. Extrusion can swiftly generate several prototype variations after the die is made, allowing for quicker testing and improvement. The quick production cycle enables businesses to modify their ideas as needed more quickly, cutting down on the amount of time needed for the entire product development process.

Strength and Durability

Because of its exceptional strength-to-weight ratio, aluminum is a great material choice for goods that need to be durable without adding extra bulk. This quality is particularly useful in sectors like aerospace and automotive, where lighter parts are necessary to increase performance and fuel economy. Prototypes made of aluminum extrusion preserve the material's natural strength and durability, enabling accurate testing in a range of scenarios. Designers can feel confident in their choices since they know that their prototypes will function similarly to the finished product.

Scalability for Mass Production

The smooth transition from prototype to large production is one benefit of employing aluminum extrusion prototyping. A design can be readily scaled up for bigger production runs after it has been tested and refined through the extrusion process. Time and resources can be saved when full-scale manufacturing uses the same dies that were used for prototyping. Aluminum extrusion is a viable choice for businesses aiming to develop concepts into products that are available for the market rapidly because of its scalability.

Aluminum extrusion prototyping offers a productive, economical, and environmentally friendly option for product development. Aluminum extrusion prototyping is a reliable method for turning concepts into robust, workable prototypes that open the door to profitable mass production.