The aerospace sector, where precision, robustness, and innovation are essential, depends heavily on precision CNC (Computer Numerical Control) machining. By allowing the precise production of highly complex and intricate parts, this technology has completely transformed the manufacturing industry. As materials and processes continue to progress, precision CNC machining has emerged as a key component of China's aerospace manufacturing industry. Plastic mold manufacturing is a noteworthy application that goes hand in hand with CNC machining; both are essential to aerospace innovations. Further in this blog, we will take a closer look at the role of precision CNC machining in China’s aerospace manufacturing:

High Precision for Critical Aerospace Parts

Strict tolerances must be followed by aerospace components since slight discrepancies might cause malfunctions or accidents. Parts that are precision CNC machined are guaranteed to meet precise requirements, frequently with tolerances as close as 0.001 inches. The production of landing gear, engine parts, and turbine blades depends on this degree of precision.

Durable Materials for Aerospace Applications

Materials that can tolerate high stress, corrosive conditions, and extreme temperatures are needed for aerospace components. Numerous robust materials, like titanium, aluminum, and stainless steel, which are frequently used in the construction of airplanes, may be machined with precision using CNC technology. Moreover, these materials can be manufactured into intricate geometries—which are necessary for strong yet lightweight aircraft parts—thanks to CNC machining.

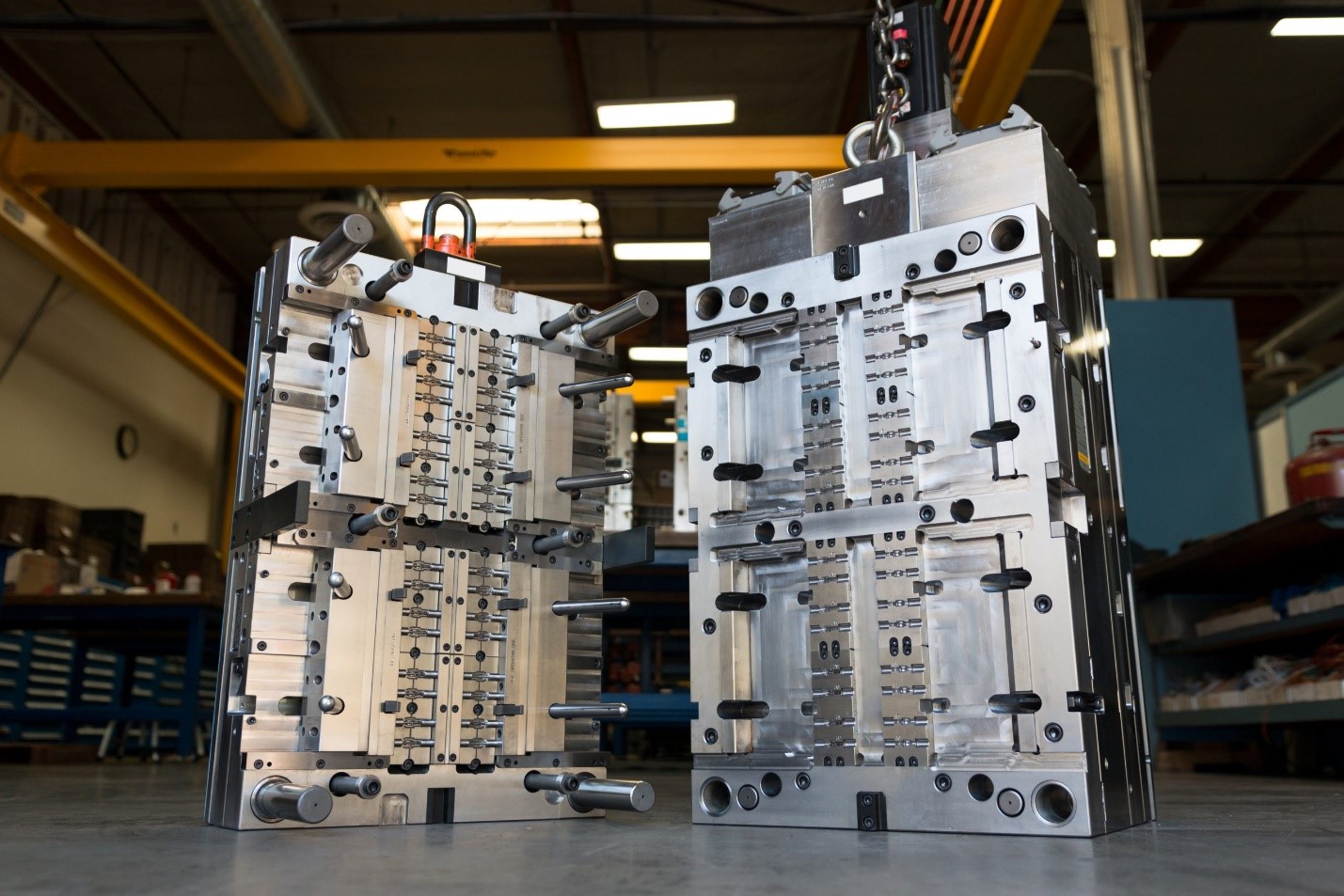

Plastic mold technologies have also been incorporated into aerospace manufacturing processes in China, particularly for components that need to be lightweight but highly durable.

Complex Geometries for Optimized Performance

The capacity of precision CNC machining in China to generate complicated geometries and intricate shapes that would be difficult or extremely time-consuming to achieve using traditional methods is one of its most notable benefits. This expertise is essential for optimizing components such as airframes, turbines, and fluid dynamic systems in the aerospace manufacturing industry. Components with undercuts, hollow sections, and other features that improve aerodynamic performance can be carved out using multi-axis CNC machines.

Efficiency and Cost-Effectiveness in Production

In the very competitive aerospace sector, efficiency and cost management are critical. Many of the manual procedures that were previously carried out are now automated by precision CNC machining, which increases output while lowering mistakes. This results in lower labor costs and material waste—two things that are crucial for manufacturing on a broad scale.

Advancements in Technology and Innovation

The technology of CNC machining is still developing, especially for use in aircraft applications. Design and production possibilities for components are being expanded by recent advancements in 3D printing, automated material handling, and AI-driven CNC processes. Aerospace producers in China are leading the way in implementing these innovations to maintain their competitiveness in the international market.

In the end

In the aerospace industry, precision CNC machining is essential, especially in China where production has been streamlined by sophisticated machinery and technology. The success of the industry depends on this manufacturing process because plastic mold manufacture is both economical and efficient, and it can produce intricate, high-tolerance parts. CNC machining will continue to be essential to fostering innovation and guaranteeing the highest caliber of products as the aerospace sector grows.