Rapid prototyping allows the quick creation of physical parts directly from CAD model data through various manufacturing techniques. It can be utilized at any stage of product development for any component or sub-component. Moreover, it can be repeated several times to meet the requirements of the new product design process with the test data. As a result, the desired part can easily be achieved.

So how can we define prototype in the simplest words? A prototype is a preliminary version of any final product. It is used to define and evaluate the design, test the technology, analyze the working principle, and provide specifications. Prototypes play a vital role in the design as well as the development of the product.

Characteristics of Rapid Prototyping

Quick manufacturing

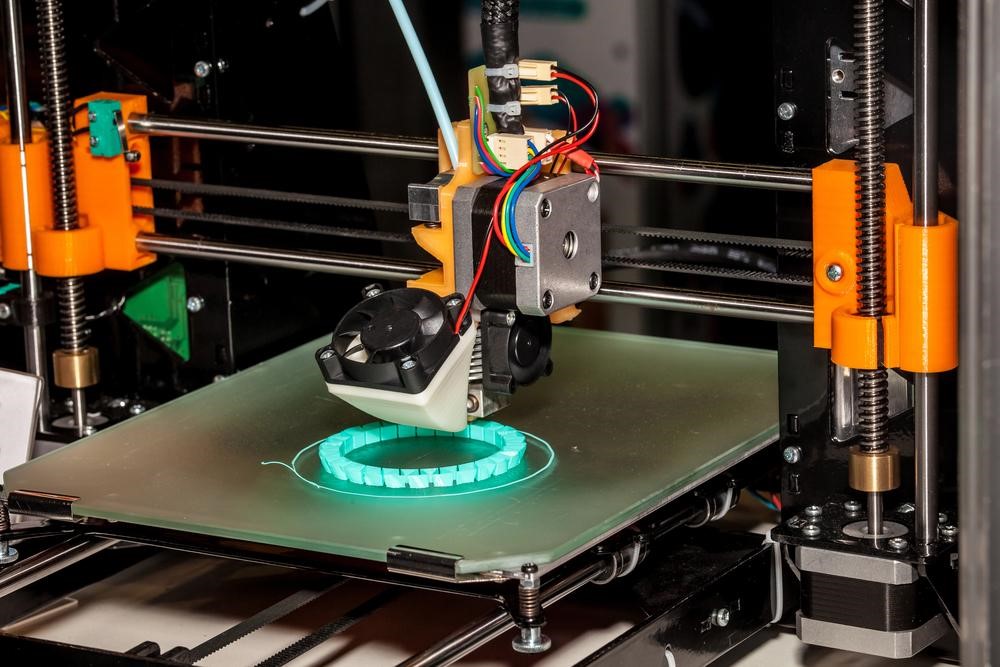

Rapid prototyping offers an effective way of manufacturing complex prototypes or parts for the engineering and designing of an end product. It can match product design with mold products which results in improved efficiency of research and development, reducing the product design cycle, and significantly reducing the cost as well as the risk of new product development, especially for products having small and complex shapes.

Integration of CED/CAM technology

Integration and manufacturing have always been cumbersome. Now, the computer-aided process cannot be connected with CAD and CAM seamlessly which also restricts the information of the manufacturing industry. However, rapid prototyping technology integrates CAD, CAM, laser technology, numeral control technology, the chemical industry, and material engineering effortlessly.

Reproduce 3D data

The parts created using rapid prototyping are easily able to reproduce three-dimensional models. Whether the outer surface has a complex shape or the inner cavity has a special hole, it can accurately complete the modeling without the need for repair using external equipment.

Works with any molding material

There are several kinds of materials used in the rapid prototyping equipment including resin, nylon, plastics, paraffin, paper, and metal along with ceramic powder. It is meant to meet the mechanical performance requirement of the products.

What is the importance of rapid prototyping?

Companies need to develop and introduce new products quickly in order to keep up with the high demand and competition. Since the faster production and innovation of the end product are vital for the success of a company, rapid prototyping becomes the most vital element. Rapid prototyping ensures a smooth process of designing products by speeding up the development process. It helps in early-stage design validation of the form, fit, and functionality.

It allows functionality testing to test the objective of the concepts as well as to finalize the product's specifications. The best thing about rapid prototyping in China is that it gives the end user, client, and participants hands-on experience which helps in getting feedback.