In the manufacturing process known as CNC, or computer numerical control machining, materials are chopped, shaped, and formed into the final product. The approach has increased productivity, accuracy, and adaptability while revolutionizing the manufacturing sector. We'll talk about the value of CNC machining in contemporary production in this blog article.

First and foremost, Precision CNC machining in China allows for increased efficiency in the manufacturing process. Traditional machining methods, such as manual milling and lathing require skilled operators to control the movement of the machine manually. With CNC machining, the process is automated, allowing for faster and more consistent production. This is especially important in today's fast-paced manufacturing environment, where quick turnaround times are often required.

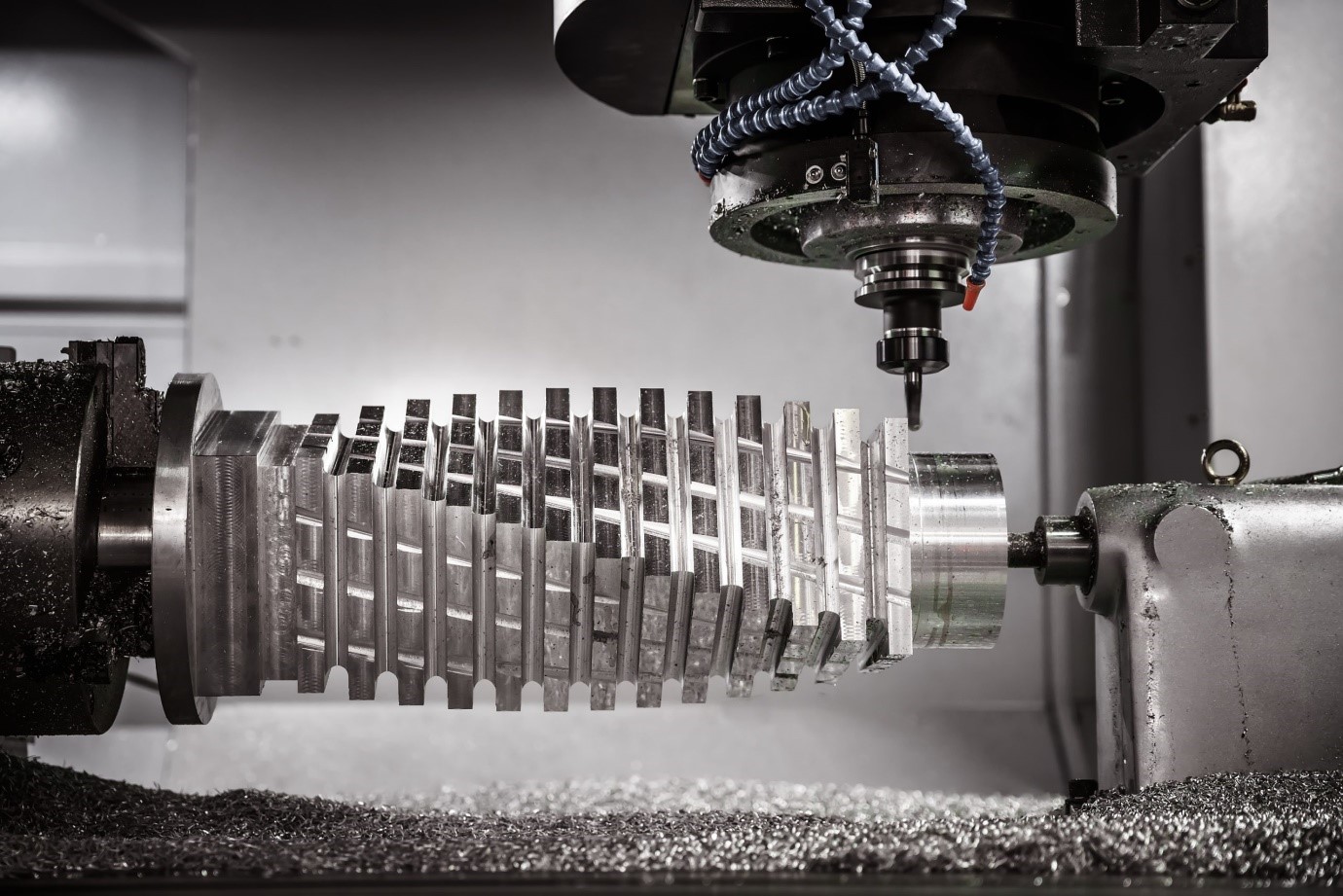

CNC machining also allows for greater precision in the manufacturing process. With the use of computer-controlled machines, the precision of the cuts and shapes made on the material is highly accurate. This is critical in industries such as aerospace and medicine, where precision is crucial for the safety and functionality of the final product. CNC machines are also capable of producing complex geometries and shapes that would be impossible or impractical to produce through traditional machining methods.

In addition to increased efficiency and precision, CNC machining also offers versatility in the manufacturing process. CNC machines can work with a variety of materials, including metals, plastics, and composites. This means that manufacturers can use a single machine to produce a wide range of products, reducing the need for multiple machines and increasing the efficiency of the manufacturing process.

CNC machining also allows for more efficient use of materials. With the ability to program the machines to cut and shape the material with precision, manufacturers can reduce waste and save on costs. This is especially important in industries where materials are expensive, such as aerospace and medical.

In modern manufacturing, CNC machining plays a critical role in the production of a wide range of products. The technology has allowed for increased efficiency, precision, and versatility in the manufacturing process. This has led to cost savings for manufacturers and improved functionality and safety for the final products. From aerospace to automotive, medical to jewelry, CNC machining is used in many different industries and is essential for modern manufacturing.

In conclusion, CNC machining is a vital process in the modern manufacturing industry. Technology has revolutionized the manufacturing process by increasing efficiency, precision, and versatility. The ability to program the machines to cut and shape materials with precision also allows for more efficient use of materials, reducing waste and saving on costs. As a result, CNC machining plays a critical role in the production of a wide range of products and is essential for modern manufacturing.