The introduction of 3D printing technology has drastically changed the product development industry. This technology is changing how items are produced, particularly in manufacturing giants like China, from rapid prototyping to final production. This is a thorough examination of the ways in which 3D printing in China is transforming the sector.

Accelerated Product Development Cycles

From concept to prototype, traditional product development cycles frequently take weeks or months, especially in China's manufacturing centers. However, designers and engineers can now create working prototypes in a matter of hours with 3D printing in China. Before switching to more costly production techniques like prototype injection molding, teams may test several design iterations rapidly, find problems early, and make the required corrections with this rapid iteration capacity. Rapid failure and iteration have revolutionized product development by drastically cutting development costs and time-to-market.

Enhanced Design Flexibility and Complexity

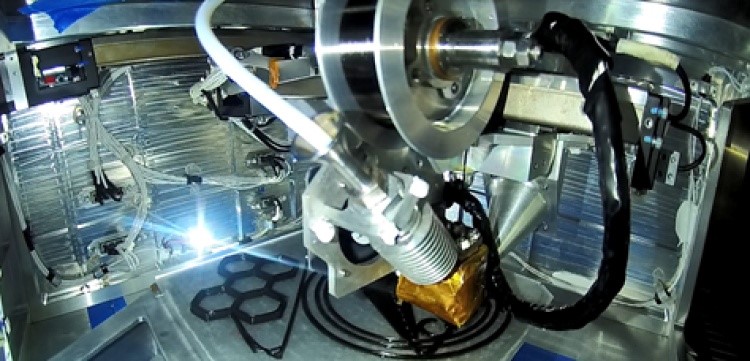

Many of the traditional manufacturing constraints have been removed by 3D printing, making it feasible to create intricate geometries that would be impossible or prohibitively expensive to produce using traditional techniques. Intricate internal structures, organic shapes, and integrated mechanics that maximize product performance are now available for designers to experiment with. From medical devices to aeronautical components, this freedom has led to ground-breaking inventions across a range of industries. The technology makes it possible to produce parts with embedded components, optimal topologies, and changeable densities to increase product usefulness while using less material.

Cost-Effective Prototyping and Small-Batch Production

3D printing has had a revolutionary economic influence on small-batch production and prototyping. Businesses can use 3D printing to create small batches or individual prototypes without having to pay high tooling expenses like they would with conventional manufacturing techniques. Small businesses and startups can now compete with larger organizations with this democratization of product development brought about by accessibility. On-demand production is also made possible by technology, which lowers waste and inventory costs.

Material Innovation and Development

Manufacturers can now use a variety of materials, such as metals, ceramics, composites, and biocompatible substances, in addition to conventional plastics. This results in functional prototypes that more closely resemble finished goods in terms of durability, mechanical qualities, and heat resistance. By allowing the production of components with different qualities and attributes, the capacity to print using numerous materials in a single build has also created new opportunities for product innovation.

Integration with Digital Design and Manufacturing

Especially in advanced manufacturing facilities in China and around the world, 3D printing has become a crucial component of the digital manufacturing ecosystem. The technology creates a streamlined digital process from design to manufacturing by integrating easily with quality control systems, simulation tools, and CAD software. Faster design validation, more precise production planning, and real-time cooperation between design teams in various locations are all made possible by this integration. 3D printing's digital nature also makes it easier to use Industry 4.0 concepts, such as automated production optimization and data-driven decision-making.

Final Words

The impact of 3D printing technology on product development and prototyping is becoming more and more important as it develops. It is an essential tool in contemporary production due to its speed, versatility, cost-effectiveness, and integration capabilities. Adopting 3D printing in China has become not only advantageous but also essential for companies trying to maintain their competitiveness in today’s fast-paced market.