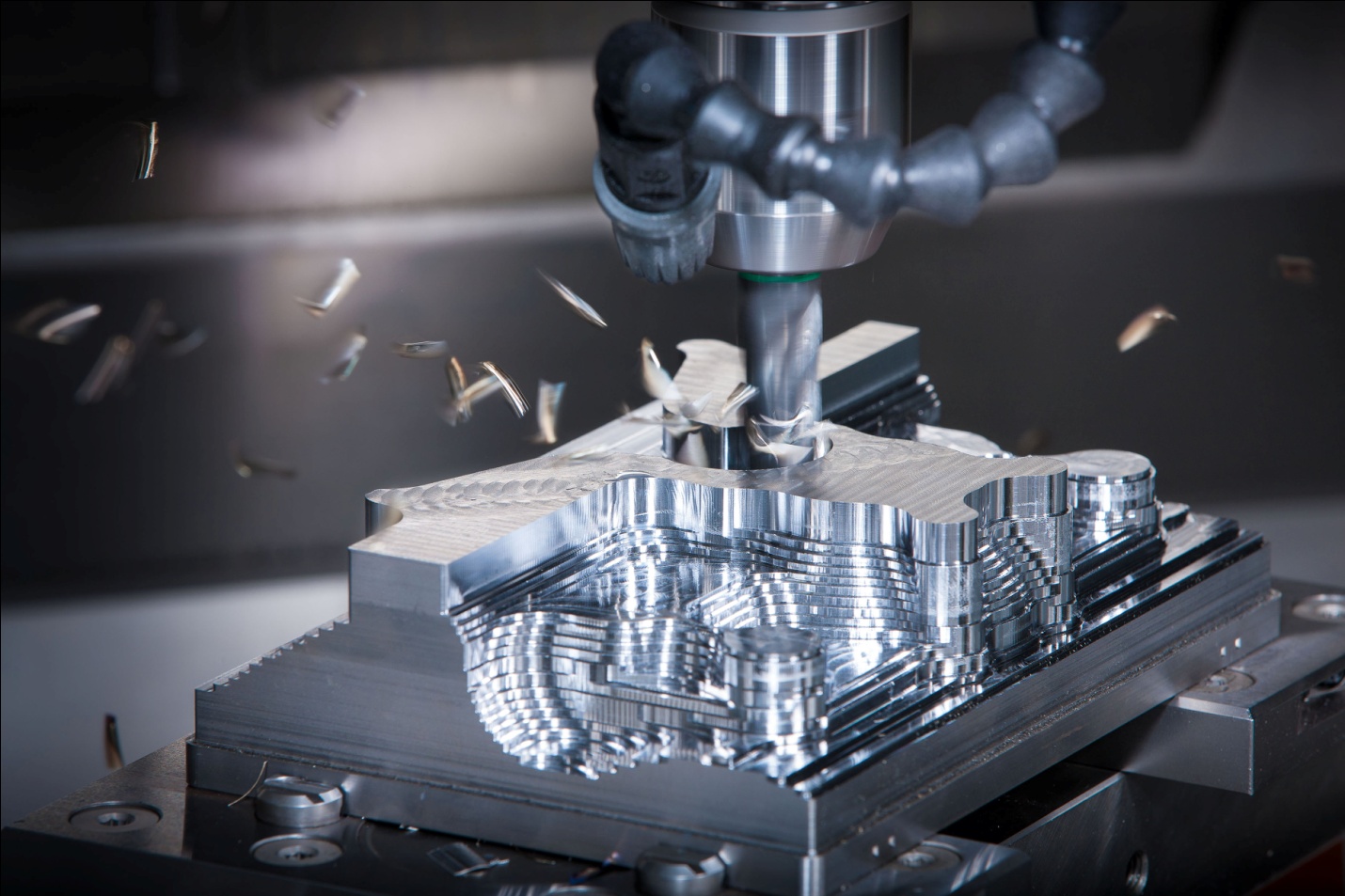

CNC or Computer Numerical

Machines have brought a revolution in the manufacturing industry of the modern

era. The advancement of technology has made computers efficient in doing

heavy-duty tasks that have reduced the stress of manpower in almost every

field. This evolution has given manufacturers of various sectors an opportunity

to utilize the advantages of CNC machining for the fabrication and

manufacturing of complex machine objects involving metal and plastic parts.

There are different machine tools such as

lathes, routers, grinders, shapers, or mills that are used in CNC machining for controlling the heavy machines

with its speed, location, feed rate, and coordination. These machines are

operated with special software that has customized G code that helps in

operating and controlling the various factors of machines. A variety of

materials such as aluminum, brass, copper, ABS, nylon, foam, titanium, steel,

wood, Delrin, fiberglass, plastic, zinc, magnesium alloy, polypropylene, etc

that are involved in CNC machining.

Different

industries that are operated with the support of CNC machining

§ Automotive

§ Agriculture

§ Metalwork

§ Electronics

§ Construction

§ Dental

§ Aerospace

§ Military

§ Firearms

§ Transportation

§ Publishing

§ Production

§ Hospitality

§ Manufacturing

Features

of CNC machining

§ These machines are capable of operating 24 hours and are only switched off during their care and maintenance.

§ They are programmed to do heavy-duty tasks like producing simple and complex machine objects of metal and plastic materials with an excellent finish.

§ Manufacturers can save a lot

of time and effort as the CNC machines release the stress of producing

prototypes that result in improving the efficiency and functionality of this

process.

What

are the benefits of CNC machining?

§ Accuracy – Speed is an important factor that matters the most in the manufacturing and production process in all the industries. Gone were the days when conventional machines were used in producing shapes and objects of complex nature, nowadays, CNC machines are used for the fabrication of metal and plastic parts with high accuracy that has almost reduce the involvement of more manpower in the development process.

§ Creating copies – CNC machines are considered best in replicating the look of repeated 3D objects without even identifying a single difference. The exact copies of prototypes are produced with precise specifications of the objects and shapes.

§ Cost-effective – Many people that CNC machining is a bit expensive process used in numerous sectors. However, CNC machines are programmed in such a way that it reduces the unit price of each part making the whole production process convenient and affordable. The machine also cuts the cost of more labors as it doesn’t require more than one skilled labor who can operate the machine to bring better productivity.

If you are involved in the manufacturing and processing process of complex machine parts then hire CNC machining

services that will help you to save the machining cost and improve the functionality of machines to meet the requirements

of consumers and industries in an efficient manner.