The primary difference between a standard metal fabrication project and a custom fabricated solution is “value.” Almost all custom metal fabrication projects start with research. That's because it helps the fabricator to assess the correct materials to produce unique fabrication designs cost-effectively.

Custom sheet metal fabrication in China can help produce long-lasting and high-quality results that deliver long-term value.

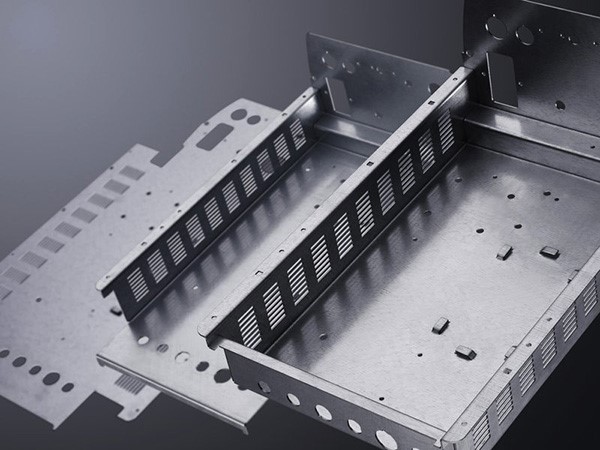

Here we’ll see a few illustrations of custom fabrication techniques that produce quality fabrications with long-term value.

1. Establishing Design Intent

In order to achieve the desired result, the fabricator will carefully consider the design of the metal fabrication project. A fabricator usually takes a standard plan or an engineering drawing to create a detailed design to accomplish the desired outcomes for even a complex project. It may require perfecting and testing the design per industry-specific requirements or regulations to serve as the building blocks for the final project.

2. Metal Cutting and Forming

The metal fabricator will choose the appropriate metal type and thickness before starting the cutting process. Fabricators go with laser cutting for delicate metal fabrications and weighty steel plates that require tight tolerances. However, lasers are not an ideal option for metal composites or materials that have impurities.

Forming the metal usually necessitates plate and angle rolling, bending, or punching. In order to obtain the desired outcome, it's critical to choose appropriate machinery. A metal fabricator will have the essential equipment in-house, which can save you both time and resources.

3. Custom Welding Capabilities and Assembling

Custom welding and assembly techniques can confirm that your project meets specific industry standards. A fabricator with certified welders and a quality control program can meet the industry requirements that add value. If you're thinking of hiring a sheet metal fabricator in China, ask for documentation of welder certifications.

In order to ensure the final fabrication project's success, it's imperative to test assemblies and subassemblies. The whole process should be documented as a part of a fabricator's structured quality control practices.

It is ideal if fabrication parts are shipped in their most complete form. Also, larger components should be shipped with big subassemblies so that you can assemble them rapidly upon arrival. The approach can drastically reduce project timelines and labor expenses.

4. Professional Finishing for Additional Value

Work with a fabricator who can increase the life of a custom metal fabrication for a return on project investment. Finishing is the last step in preparing metal products, a critical component for any metal fabrication project. Finishing helps to make products more resistant to corrosion while offering higher electrical, chemical, or tarnish resistance.

Furthermore, finishing gives additional durability and makes metal surfaces appear their best. Since metal finishing includes more than one process, it can be executed in several different methods.

When selecting a sheet metal fabrication in China, make sure to do your research thoroughly, as not all fabricators can offer the same quality of work. Choose an experienced fabricator who can deliver a quality product and measurable bottom-line value to you.