Creating a prototype is a crucial thing done before the actual production in a large scale. This is the test of what the final products will look like and how they will work if they are machines to be used in the manufacture g industry. Plastic is most common material used in the prototyping as it is easy to mold, cheap and easily available. But one problem is as plastic is easy to mold, this won’t be that easy for your to make the products of kind of the material you want. And also, the precision and quality of the final product might not be as you have thought of based on your prototype. SO prototyping or making prototype of the same material to be used in actual production is fast getting into trends.

Prototyping using the same material may cost you a little more compared to the plastic. But it won’t with CNC machining, the most effective method of creating prototype. It is capable of creating prototype using any material such as plastic, metal, etc. And the process is fast and it allows you to make the prototypes in as much quantity as you want. You can also build a single prototype with CNC machining. And the best thing is that with CNC machining, you can create the prototype with exactly the features you want your actual products to have. So you can predict how your products are going to do in the market. And thus, you can change to your concept or ideas to make a good start.

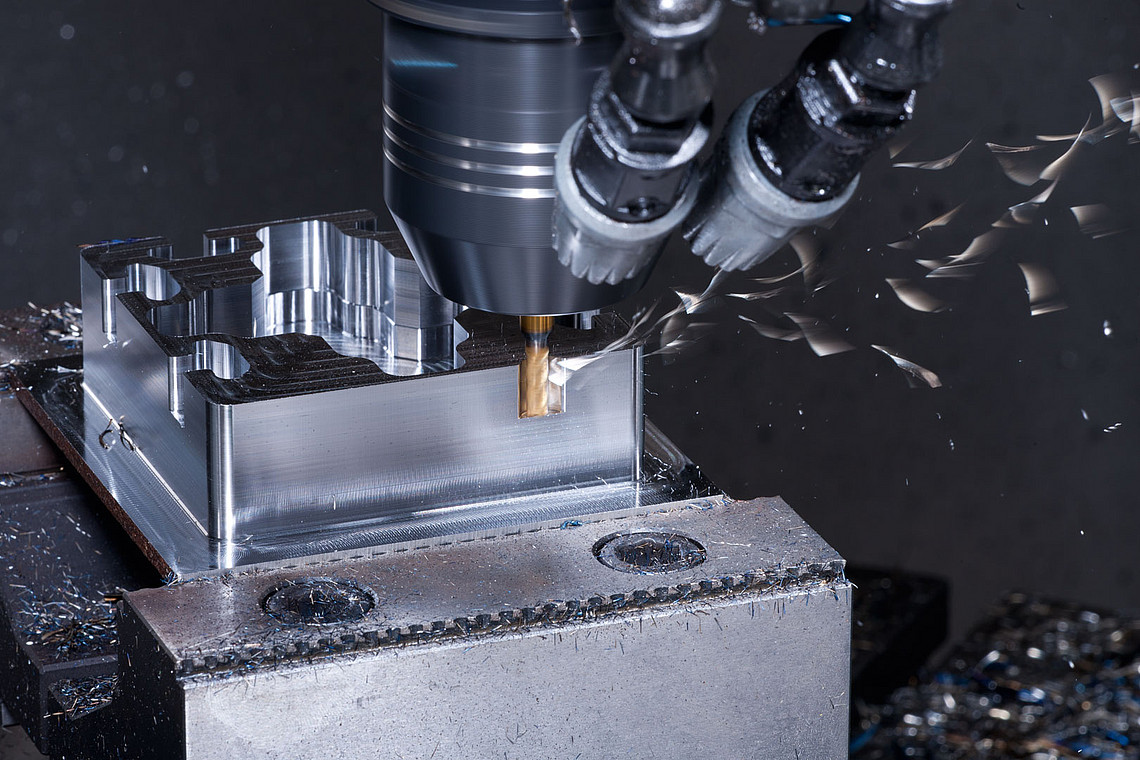

What Is CNC Machining?

CNC machining is a manufacturing process that uses pre-programmed software to dictate the movement of factory tools and machinery. It allows for controlling many different types of machines. This is what enables you to be able to create any kind of shape. You can create even a 3 dimensional blocks and all that in a single set of prompts.

The desired shape is fed into the software, so as the CNC machine is hit on, reading the shape fed in the software, the required tools, and machinery are activated to carry out the required task. It is a computerized process; this brings in more precise result and the time is significantly reduced.

In CNC programming, a code generator within the numerical system is used. This code generator ensures the mechanisms are flawless when a CNC machine is directed to cut in more than one direction simultaneously. And the placement of a tool in a numerical control system is done through part program. So the tool which is meant to do the desired task is automatically activated.

CNC machining has become more popular in China over the last few years. From startups to established large entities, they all increasingly rely on CNC machining when it comes to prototyping. As a result, more CNC machining services providers have popped up, catering to CNC machining needs of businesses. But if you are looking for quality result and all that at the most reasonable cost, you can completely rely on Uidea Rapid Prototype, a name that is widely renowned for quality rapid prototyping and tooling services.