In the last

few years, the new generation of computer programmers and engineers has changed

the practice of machining into something more of a precision art, known as

computer numerical control (CNC).

Particularly

the manufacturing industry tends to depend quite heavily on precision CNC machining

by replacing some operations that earlier required engineer operated equipment

such as routers, shaping machines, and vertical millers.

Before we get

into the benefits of Computer numerical control, take a look at what it is

exactly.

What is CNC machining?

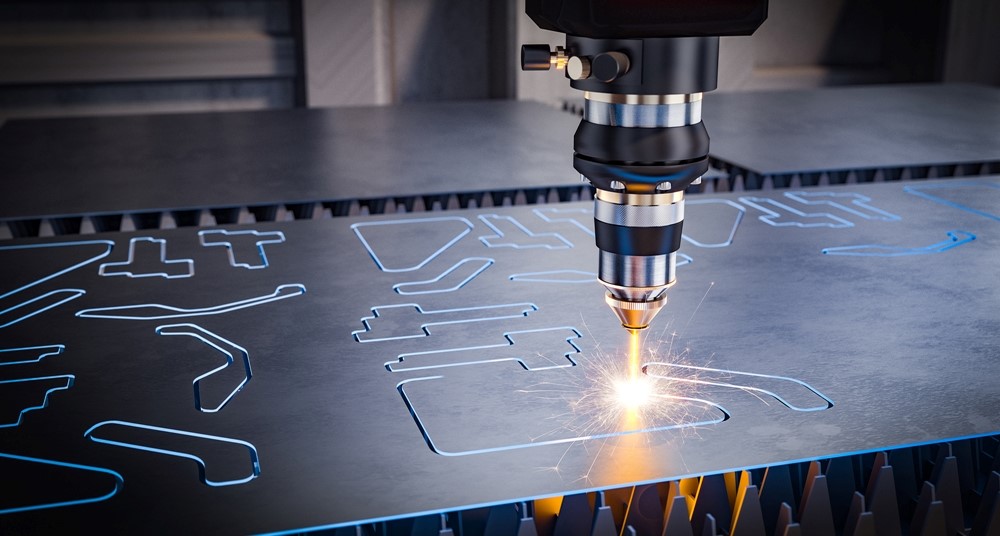

Computer

numerical control (CNC) is defined as the process that incorporates computers

so as to have control over certain tools which create various types of

products. CNC machining generally tends to incorporate common tools like

routers, grinders, mills, and lathes. These machines need specialized and

distinct software in order to function and operate properly.

Before

starting off with the machining process, a custom computer program is utilized

for designing the object which required to be machined. The computer program,

then, helps the operator have control over the machine tools, and also over

aspects such as velocity, feed rate, speed, etc.

Now that you

have an idea of what CNC machining is, it is time to learn about the

benefits that are associated with it. Some of these benefits are as follows.

· Save on manufacturing costs:

With the help of a CNC

machine, you are able to take complete advantage of all the raw materials used

in the production process. Due to their accurate way of operation, they tend to

significantly reduce waste during the manufacturing process. This lets the CNC

machine operator to minimize any sort of losses they may incur and, hence,

increase profitability over the course of time.

· Increase in the speed of production:

Precision CNC

machining is considered to be an extremely efficient process. Due to this, the

manufacturing process of a CNC machine tends to cut down on the number of steps

involved to produce a particular part. Hence, you are able to produce or

manufacture numerous parts or items in a much shorter period of time as

compared to the other manufacturing techniques.

· Increased safety:

The entire production

process within a CNC machine is automated. So, the operator of the machine is

not even involved in the manufacturing process at all. This tends to be a safer

process due to the fact that it is the machine that does all the legwork

without needing any operator present to operate it. CNC machining is almost

always so accurate that it rarely tends to pose any sort of safety risks.

· Increased efficiency of production:

A CNC machine is

arguably the most efficient system to design components. This is made possible

because of the fact that many of the CNC machines are equipped with quality

assurance protection measures installed within them. So, any time you face a

problem in the production process, the machine successfully detects it and it

either shuts down completely to prevent further damage or fixes the problem

internally.

These were some of the significant benefits of a CNC machine in the production process. By now, you must be aware that this is far better as well as safer than the other conventional methods available. So, it is better to invest in it and get done with your manufacturing process quickly and efficiently.