Aluminum is one of the most successful commercial metals today. It is a material that has been used for constructing long-lasting and lightweight components across industries, such as aerospace and aeronautical, military and defense, and other industries.

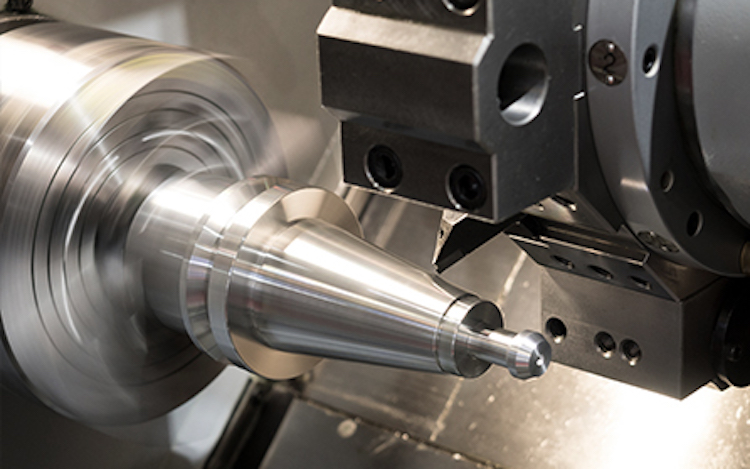

CNC machining in China is preferable because it

helps manufacturers achieve accuracy, repeatability, and high productivity. Compared

to many other manufacturing processes, CNC machining enables manufacturers to

make the best use of material properties. These features have been made to best

use by CNC aluminum machining services.

In

recent years, material combined with CNC machining has contributed to the

demand for CNC machined parts. Here are some of its benefits:

1. Great Strength to Weight Ratio

Because of aluminum's high strength-to-weight ratio, the demand for its parts has increased over the years. Aluminum possesses high strength, and yet it is lightweight. Both these properties make it an excellent option for constructing crucial components in the aerospace and automotive industries.

2. Highly Customizable

Aluminum can be personalized to meet the application requirements. CNC machined parts can be cosmetically improved or finished to preferred outcomes.

3. Withstand Temperature Variations

Aluminum, as well as steel, has been widespread for many years. These two metals provide benefits that make them a great choice for several industrial applications. Although more durable, steel is not an ideal option if temperature variations are involved.

For instance, steel cannot resist high welding temperatures or low temperatures. On the other hand, aluminum can withstand both extreme conditions efficiently.

4. Recyclable

Aluminum parts are also highly recyclable. This factor has contributed to their increasing usage in industrial applications. CNC machined aluminum components are the right choice for businesses looking for ways to reduce their carbon footprints.

CNC machining is a subtractive process, where a lot of material waste is created due to chipping. Waste of materials can be recycled to produce a more effective product.

5. Anti-Corrosive

CNC machined components made of aluminum are used in several applications where they are exposed to corrosive elements. Although aluminum provides resistance to corrosion, its capabilities of corrosion resistance vary across grades.

6. Highly Machinable

Aluminum is a robust material, but it chips efficiently, making it easy to convert into a desirable shape. The material can withstand rigorous punching, folding, and drilling conducted during CNC machining without losing its material properties. Because of its easy-to-shape feature, the energy needed to machine aluminum is less compared to other materials.

7. Great Electrical Conductivity

Because aluminum is a good

conductor of electricity, it can be used in electrical applications. It may not

have the same level of conductivity as copper, but it is better than steel and

other widely used machined materials.

Conclusion

Aluminum is not a difficult

metal to machine, but it is better to work with the right CNC machining company in China. If you are looking for CNC machined

aluminum components for your aerospace applications, defense projects, or any

other project, choose a partner specializing in CNC machining and delivering

precision CNC machined parts to its clients.