What are machines used for? To reduce human effort. However, traditional machine functioning always includes human effort that is prone to errors, as human work can cause some slips some time.

This is where CNC machines have arrived in the picture.

What are CNC Machines?

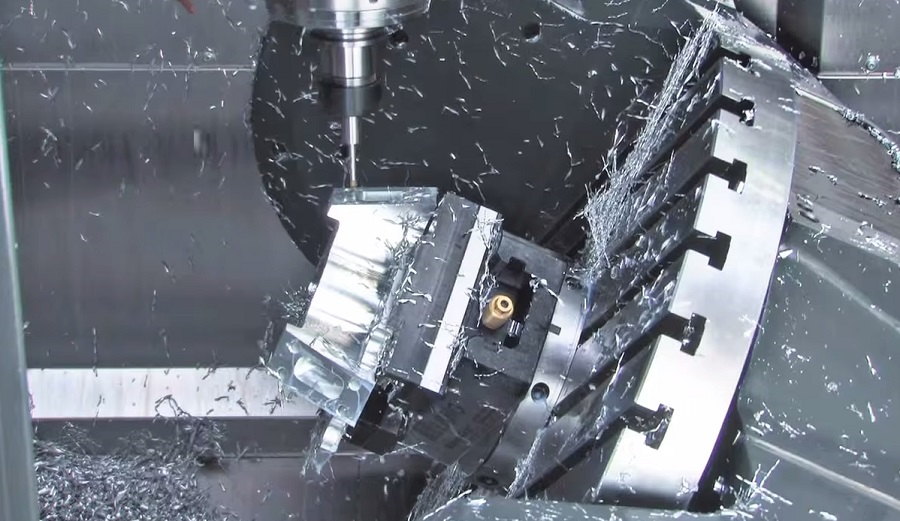

CNC stands for – Computer Numerical Control. The use of CNC machining is all about eliminating the human intervention whilst controlling the work-piece and tool using a numerical program.

CNC machining in China, or globally, has become a highly adopted activity in different industries. CNC machines function based on CAD and CAM approach. The fundamental element is using a computer to control machine parts, used across small-scale and large-scale industries, repair shops and roadside workshops, and more.

Advantages of CNC Machining

· High automation use that reduces the intensity of labour effort.

· Result in achieving product consistency in manufacturing and design, at a faster rate.

· Achieve prototype machining’s complex processing.

Applications of CNC Machining

Some of the common uses of CNC machines are in:

· 3D Modelling and Prototyping

Precise prototyping and modelling is an essential aspect of production process in an industry. CNC allows for scanning, copying, engineering and reverse-engineering components to create advanced products and move on the to net concept step, with accelerated project timeline and high accuracy in result.

· Brass and Aluminium Machining

When there is a need to cut non-ferrous metals like brass or aluminium, precise cutting methodology is needed with more attention. CNC machines help to create precision based cutting process, whilst also improving timeline and reducing the effort and costing. CNC machining helps in proper utilization of feed-rate and RPM spindling, ensuring effective interaction with blades.

· Signage Creation

CNC machines help to get effective results for complex 3D signage component as well as a small-scale 2D component. CNC routers are employed that are effective to work with wide variety of materials like wood, brass, aluminium, foam, acrylic, plastic and more, resulting in high accuracy and efficiency for crafting carvings or signage.

· Musical Instrument Creation

Musical instruments need to have each and every component in the right order and with precise finish. CNC machines help to cut the instrument parts to defined specifications, thereby developing a structural frame that ensures high-end interaction for delivering sounds ranges.

· Cabinet Manufacturing

Whether it is the production of standard or customized cabinet and furniture, CNCs help to cut the cabinetry to detailed specifications. CNC machines allow for high precision, fast and accurate development of chairs, doors, tables, countertops, closet sets and more with full efficiency.

CNC machining in China, as well as other countries’ industries are applied for a wide range of precision cuts and production process enhancement.