In the manufacturing industry, sheet metal fabrication is a common manufacturing option due to its high versatility and low-cost operation. Sheet metals are thin metal sheets with a thickness ranging from 0.4mm to 6mm. Some examples are steel, brass, copper, aluminium, and nickel alloys.

In this blog, you will learn about the key considerations that you are expected to know while communicating with a sheet metal fabricator in China about your project requirements.

Key Considerations to Keep in Mind for a Sheet Metal Fabrication Project

Ø Material

The type of material used for sheet metal fabrication depends on the application, weldability, formability, corrosion resistance, strength, weight, and of course, the cost.

Ø Size

The thickness of sheet metal you choose depends on the strength of the part or component you intend to form.

Ø Designing

To convert an idea into a real object, a sheet metal fabricator needs to know the following parameters:

· Wall Thickness

· Bend Radius

· Bend Allowance

· Bend Deduction

· Bend Reliefs

· Holes & Slots orientation

· The K Factor

· Additional features such as hemming, notches, curls, countersinks, etc.

Ø Drawings

First of all, you will need to create a 3D model on the computer, and then your engineers are required to provide the drawings for manufacturing. To show bend lines, flat patterns are included, and a bend table is attached that shows the angle and the bend direction. Drawings need to be accurate and precise as they provide the information that will be used by the fabricators for manufacturing the intended parts and components.

Ø Finishing

You also need to decide on the finishing of the sheet metal fabricated product. Most often, this aspect is chosen based on the cost, desirability, and the application of the manufactured parts. While some finishes are done to enhance the strength or durability, other finishes are purely for aesthetic purposes.

Ø Manufacturing Method

With the help of engineers on your team and the experts provided by the sheet fabrication service provider, you can also determine what kind of manufacturing methods are suitable for your project. There are a variety of manufacturing methods available, such as:

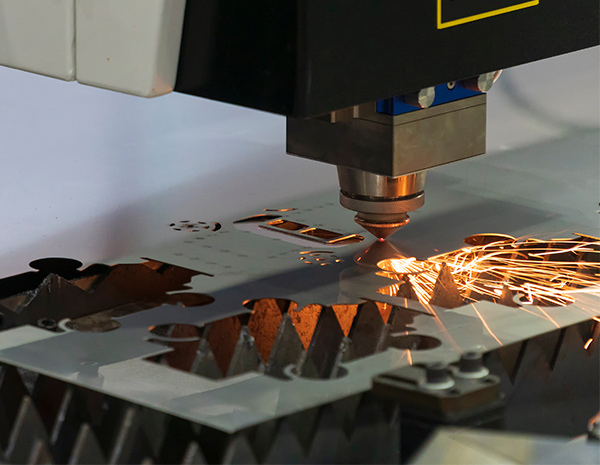

· Cutting: Laser cutting, Water Jet Cutting, and Mechanical Shearing

· Bending: Point bending, Roll bending, Incremental bending, Air bending, and more

· Drawing: Involves drawing of the sheet metal blank into a forming die to obtain a hollow or curved surface

Ø Fabrication Process

During the fabrication process, the sheet metal model is formed according to the specifications and drawings, and then other methods like welding, riveting, and brazing are used to join edges and close the gaps to maintain the strength and design of the intended part.

Ø Post-Process Finishing

The joints and closed gaps are required to be surface finished so that there are no sharp edges. This also helps in enhancing the aesthetic appeal of the part. Finishing tools used for this purpose include hand grinding, wide belt sandpapers, buffing, sandblasting, jitterbugging, etc.

Once you are aware of all these things, it would be a breeze for you to communicate with any sheet metal fabrication company in China at the same level.