The substantial reason for creating prototypes of

any object is to verify the design intent for the production, and the same

applies to sheet metal prototyping.

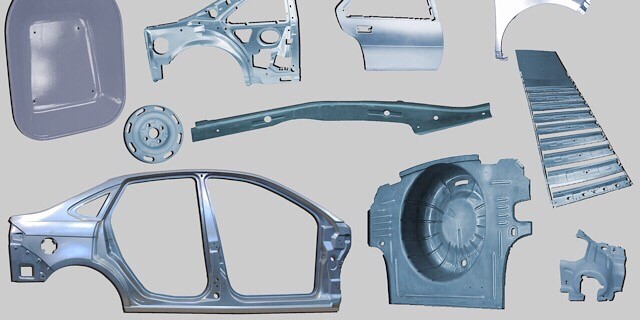

It is a process of forming metal sheets into desired shapes using various

manufacturing techniques. The process involves various steps from cutting to

bending to surface treatment and assembling.

You must be aware of the types and methods of

production in sheet metal prototyping projects, but there are some factors that

you should pay attention to when choosing the sheet metal prototyping company.

Choosing an experienced sheet metal prototyping company makes a huge difference

in the successful and smooth completion of a manufacturing project. These

companies understand the need for being technically advanced in communication

processes and production machinery. It will enable them to enhance their

production capacity and fulfill customers’ requirements for effective communication.

Here are a few factors that you should consider

while starting a sheet metal prototyping project:

Communication aspect

When you hire sheet metal production services from a

company, you need to be able to trust the company. Communication is one such

significant factor that enables clients to put their faith in the manufacturing

partner’s abilities. You should be able to trust the company’s manufacturing

process and the team whose hands will be directly working on it. Make sure that

the company is responsive and maintains regular communication with you. The

best companies ensure that all your queries are answered without any delays.

Understanding the project requirement

It is a vital need of any production project. The

company you are considering for the production project should be able to

understand the project requirements precisely. They should be able to assure

you that their team is capable to provide you with the precise design of your

product just as you want. The company should have skilled design engineers who

can develop prototypes and bring your concept to design.

The choice of materials

To complete the production project successfully, the

sheet metal prototyping companies rely on the procurement of cost-effective

materials to a great extent. Make sure that the production teams are sourcing

the best quality materials for the sheet metal prototyping project while

keeping the cost in check. The thickness of material depends on various

factors, including the design, style, or application of the object.

Effectiveness of production flow

After sourcing the right materials, the company can gain an advantage by applying the most appropriate method of production considering the production requirements. For instance, they can consider choosing the laser cutting method, which is a quick, accurate, and efficient way of cutting sheet metal.

The production process of sheet metal prototyping depends on various other aspects, including metal forming using press brakes, welding to join metals permanently, and hardware insertion. The choice of production process depends on all these factors, and choosing the best manufacturing method will speed up the process significantly.

Conclusion

The metal sheet prototyping company you choose for your production project is as much involved in the project as you are till the completion of the project. Make sure you choose the best ones considering the factors mentioned in this blog when finalizing the deal.