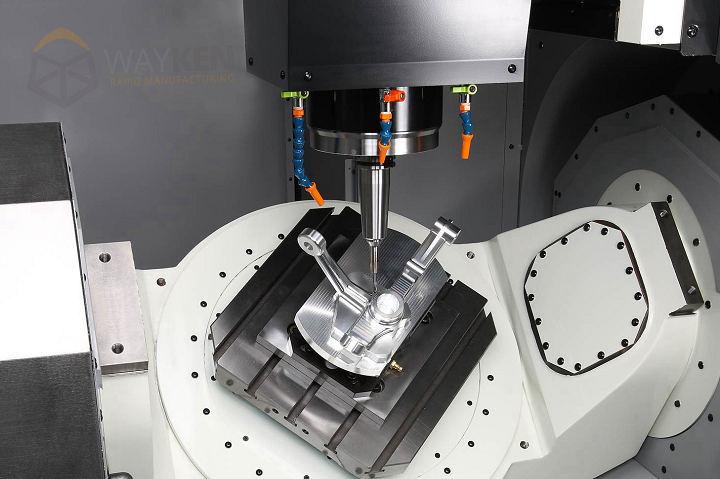

CNC machining is a widely used manufacturing

process to form assembly parts and other products from sheet metal or other

materials in a wide number of industries. It uses automated and high-speed cutting

tools for precision cutting to create multiple identical products at once to

reduce production costs. There are many factors that affect CNC machining costs

for industries depending on their specific requirements and needs.

Well, before you start using CNC machining services

in China or any other part of the world to manufacture products for your

industrial application, make sure to know about factors that affect CNC

machining costs to control your production cost. The CNC machining costs can

vary depending on your part design, what you’re using it for, the material you

are using, and many more things as per your specific requirements. Also, you

may need different CNC machines and processes that could also affect your

production cost. The main factors that affect CNC machining costs include:

1. The specifics of your order

2. The cost of your material

3. Finishing costs

The specifics of your order

Specific of your orders such as your order volume

and design complexity can have a huge impact on your overall product cost. More

complex and intricate designs require more precision works and CNC machining

services to finish the high-quality product. The designs will also take longer

to program and your company will charge for the time spent on the designing

process.

The cost of your material

The CNC material you use to create your products

will also have an impact on your production budget. A variety of metals such as

aluminium, steel, titanium, brass, copper, magnesium, and plastics such as

Nylon, PMMA, PEEK, Nylon+, UHMWPE, PET, PTFE are used to design products using

CNC machines for a wide range of industrial applications. Plastics are cheaper

than metals because of their less durability and lower final product cost.

Finishing costs

Choosing a finish for your products may also impact

how much you pay for CNC machining services. Some finishes offer more aesthetic value and some

finishes are used for tactical purposes for specific industrial applications

and uses. Some specific finishes are used to make your product more durable in

the long run. You will have the following finishing options to decide before

placing your order:

· A gloss finish

· Matt finish

· Mirror polishing

· Paint finish

· Laser engraving

· Tampography finish

· A soft-touch finish using a soft rubber-like layer

The type of finish you choose for your product will

affect your CNC machining cost, so make sure to choose a finish that best fits

both your requirements and budget.

As you see, these are the key factors that decide how much you will pay for your CNC machining project depending on your product type and quality. Labor costs and turnaround time may also impact the cost of your final product.

At UIDEA, we offer custom CNC machining

services in China,

with state-of-art equipment and methods with utmost accuracy and precision at

the most affordable rates. We serve industries including electronics,

healthcare, telecommunication, automotive, computer, and industrial equipment

manufacture for a variety of CNC machining projects to meet project

requirements in budget.