In the ever-changing world of product development, manufacturers are always looking for effective and affordable ways to bring creative concepts to life. With its many advantages that improve final products and accelerate the process of creating prototypes, aluminium extrusion prototyping has become a popular option. Utilising it can greatly increase production efficiency and product quality for China mould manufacturers. The following are aluminium extrusion prototyping's top five advantages for product development.

Cost Efficiency

Aluminium is formed into desired forms by forcing it through a die during the extrusion process, which reduces material waste. By ensuring that just the required amount of aluminium is utilised, this technique lowers the expenses related to material excess. Aluminium extrusion is often less expensive to set up and tool, which makes it a good option for generating prototypes. Furthermore, the extrusion process's speed and effectiveness can cut labour expenses and manufacturing time even more.

Design Flexibility

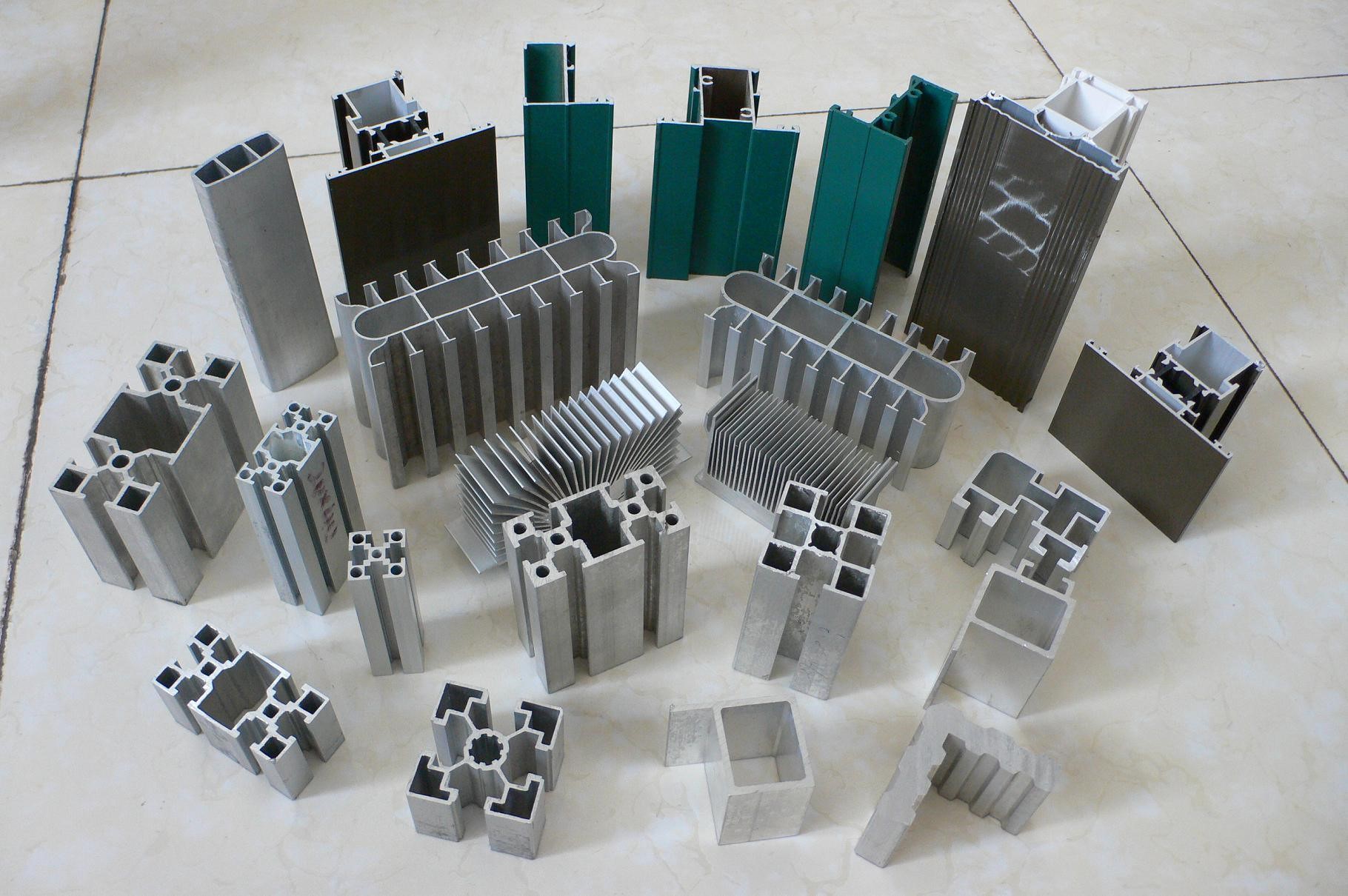

Complex geometries and complicated designs that could be difficult or impossible to achieve with conventional production methods can be created with aluminium extrusion. With this versatility, designers can test out different features and shapes throughout the prototyping stage, ensuring that the finished product satisfies all functional and aesthetic requirements.

The ability to customise extruded profiles is very useful for mould manufacturers. Prototyping using aluminium extrusion makes it simple to make changes and tweaks, giving you the chance to improve designs and take customer input into account before going into large-scale production. The final product will be optimised for both performance and manufacturability thanks to this versatility.

Strength and Durability

With its exceptional strength-to-weight ratio, aluminium is a great material for prototypes that need to be lightweight and durable. Extruded aluminium prototypes are durable enough to survive extensive testing and use, and they offer precise insights into how the finished product will function. Prototypes' natural resistance to corrosion is further increased with aluminium. Prototypes that are subjected to severe environments or demanding applications will benefit greatly from this property, which will keep them functional and dependable throughout the testing phase.

Rapid Prototyping

As extrusion is a reasonably quick technique, prototypes can be produced quickly. This speed is essential for cycles of product development since it allows manufacturers to quickly iterate designs and accelerate product launches. This capacity to prototype quickly is crucial for Chinese mould manufacturers to maintain their competitiveness in the international market.

Environmental Benefits

Aluminium is an environmentally friendly prototype material as it is highly recyclable. Utilising recycled aluminium in the extrusion process lessens its negative effects on the environment and supports environmentally friendly production methods. In comparison to other manufacturing processes, the aluminium extrusion process uses less energy, making it an energy-efficient method. Energy efficiency contributes to lower production costs and a smaller carbon footprint during the manufacturing process, which is in line with international efforts to support sustainable business practices. It can help mould manufacturers gain a better image and attract clients that care about the environment.

Aluminium extrusion prototypes have many advantages that can greatly improve product development in China. Aluminium extrusion offers a flexible and efficient way to make high-quality prototypes. You can meet market demands with innovative goods while cutting costs and streamlining development processes by utilising the benefits of aluminium extrusion.