To ensure the success of your manufacturing projects, you need to select the best precise CNC machining service provider. However, making the right choice can be difficult in China due to the abundance of vendors in the market. So here are essential factors that will assist you in choosing the ideal provider for precision CNC machining in China.

Evaluate Experience and Expertise

When it comes to precision CNC machining, experience and proficiency are crucial. So look for a service provider with experience in your particular field such as consumer electronics, automotive, and aerospace. Experienced businesses will be well-versed in a variety of materials and machining methods, guaranteeing that they can precisely fulfill the demands of your project.

Furthermore, handling intricate designs and close tolerances is a skill that an experienced provider will possess, which is essential for high-precision applications like injection mold manufacturing.

Check Quality Control Measures

Trustworthy service providers implement strict quality control procedures to guarantee that each component satisfies the required criteria. Inquire potential suppliers about their certifications, inspection equipment types, and quality assurance procedures.

Numerous elite CNC machining companies in China follow global quality standards like ISO 9001. You can feel more at ease knowing that your selected provider prioritizes quality throughout the entire production process if you make sure they hold these certifications.

Assess Technological Capabilities

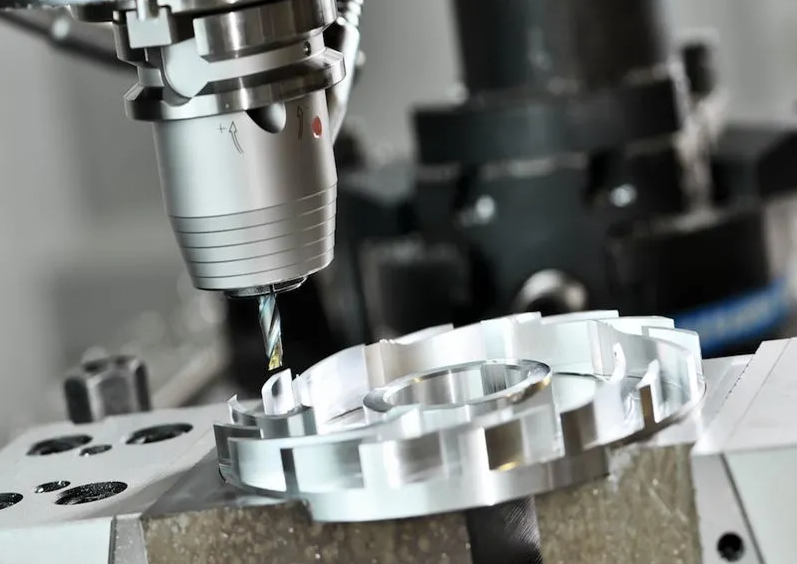

A CNC machining service provider's technological capabilities might have a big impact on how your project turns out. So look for providers who use cutting-edge CNC equipment and software. More sophisticated geometries, tighter tolerances, and a greater variety of materials can be handled by sophisticated machinery.

The top CNC machining companies in China make significant investments in cutting edge technology. This comprises high-speed machining centers, multi-axis CNC machines, and sophisticated CAD/CAM software. Providers who keep up with technology developments are more likely to maintain high standards of accuracy and efficiency in their operations and to present creative solutions.

Consider Lead Times and Flexibility

In manufacturing, prompt delivery is essential, and lengthy lead times can cause major disruptions to your entire production schedule. When selecting a CNC machining service provider, find out how long their lead times typically take and whether they can accommodate large or urgent orders. A trustworthy supplier should be able to adjust production to your demands and provide flexible scheduling alternatives.

Evaluate Customer Service and Communication

Successful collaboration with a CNC machining service provider requires clear communication and top-notch customer support. From the first questions to the post-production assistance, the supplier should be receptive, open, and ready to take care of any issues right away.

To sum up

These are the factors that you need to assess while Selecting the best precision CNC machining service provider in China. You can make sure that your project is finished with the utmost accuracy and efficiency by taking these aspects into account. Choosing a supplier with the appropriate knowledge and resources is even more important for projects with complex designs or particular needs, such as injection mold production. To make an informed choice, don't be afraid to do extensive research and pose pointed questions.