Advances in science and technology have made everything on the earth easy, be it traveling, treatment, or manufacturing metal or plastic parts. And CNC machining is one such advent that has made it not only easy to manufacture metal and plastic parts but it also ensure highest level of precision. CNC machining has become a crucial part of metal and plastic parts making industry.

Countries like china make the best use of CNC machining. This technology is widely used by prototyping tooling companies in China. This allows for the production of moulds of high precision quickly. And the best thing is that molds or prototypes can be created in any size of amount. If you are looking for a company that provides tooling and prototyping services in China, choose the one that use CNC machining along with other world-class infrastructure.

What Is CNC Machining?

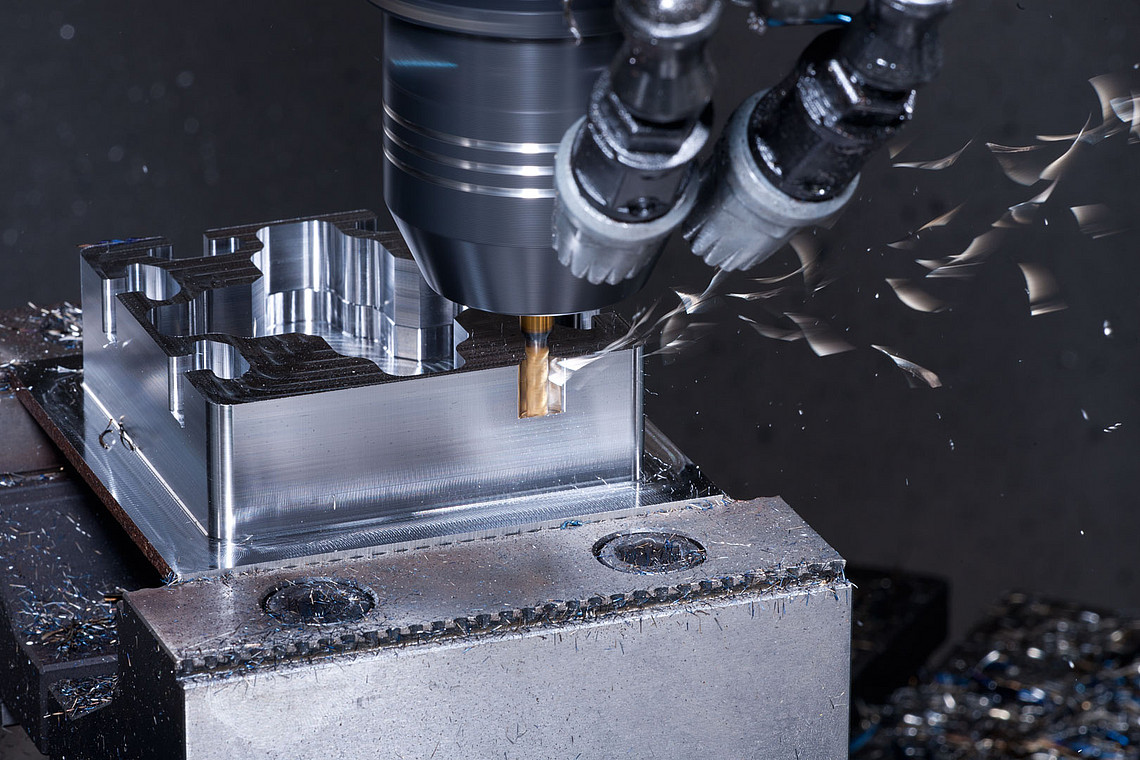

CNC Machining is a process that is widely used in the manufacturing sector which requires the use of computers to control machine tools. This process allows you to control a wide range of tools such as lathes, mills, routers and grinders. The CNC in CNC Machining stands for Computer Numerical Control.

CNC machining looks much like a normal PC controls the machines, but it is quite different from that and uses a unique software and control console that allows for controlling various tools.

With this process, machine tools are controlled using numerical control codes. The best thing is that a computer program can be customized for an object and the machines are programmed with CNC machining language (called G-code). That language controls all functions such as feed rate, coordination, location and speeds.

That is not all. With CNC machining, exact positioning and velocity can also be controlled through computer. This is what makes CNC machining the best choice when it comes to manufacturing metal and plastic parts. The method is used in manufacturing both metal and plastic parts.

First of all, a drawing is created using CAD. And once the drawing is created, a code that the CNC machine will understand is created that. The program is loaded and finally an operator runs a test of the program to ensure there are no problems. This whole process of trial is called cutting air, and it is very crucial thing to do to see if there is any mistake with speed and tool position.

There is a long list of benefits CNC machining provides. However, I have figured out some most crucial benefits that you will have from CNC machining. These are:

· The process is more precise than manual machining

· Capable of producing even complex shapes that are not possible with manual machining

· The process can make 3D and 2D shapes

· Perfect for a job that that requires high level of precision and very repeated task

There are tooling and prototyping companies in China that provide CNC machining services for those who want to make molds of the products they want to come out with.