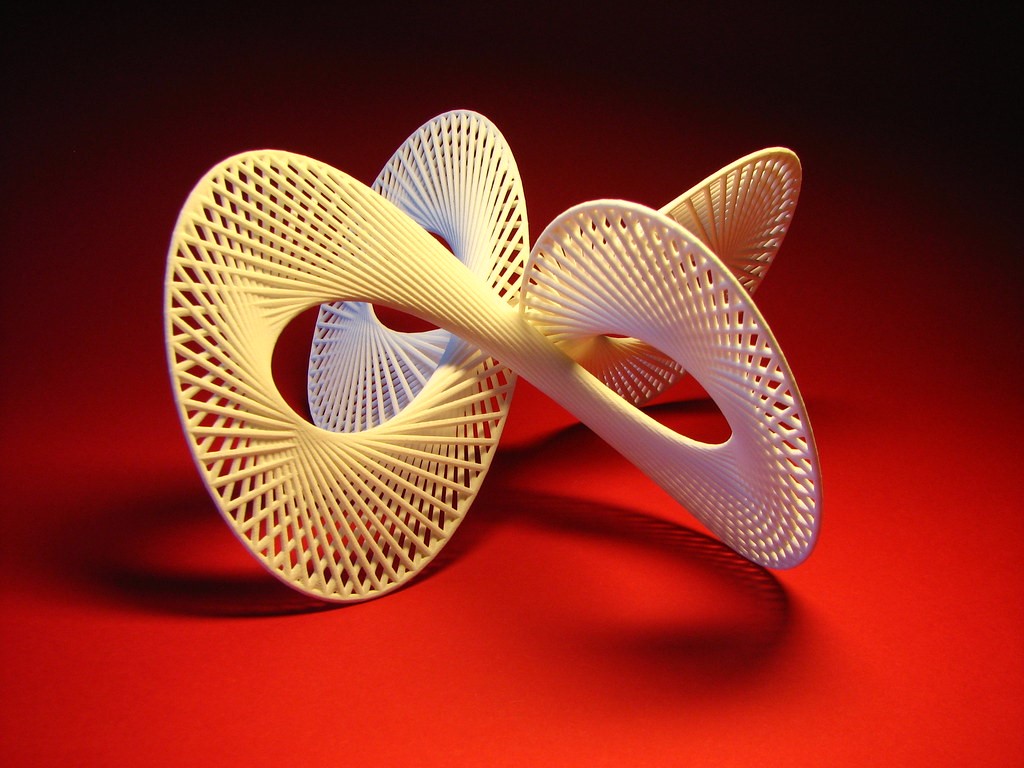

Recently, the design, prototyping, and production of products have seen a huge transformation due to additive manufacturing technologies such as SLA (Stereolithography) and 3D printing. SLA 3D printing is a kind of additive manufacturing that creates a physical object from a digital model with the help of photopolymerization. Its process includes curing a liquid resin with a light source, usually a laser or a projector, layer by layer until the object is complete. This creates accurate and detailed parts making SLA 3D printing in China perfect for creating complex geometries and small and intricate details. Now let’s explore in detail why you should consider SLA 3D printing for your next project.

Rapid Prototyping

3D printing in China printing enables rapid prototyping to help engineers and designers to quickly iterate and improve their creations. SLA technology allows for the rapid and highly accurate production of complicated geometries and intricate details. This fast speed of prototyping shortens the time it takes to launch a product and fosters creativity more quickly.

Customization

The capacity of SLA 3D printing to create unique and customized components makes it stand out. It gives designers the freedom to modify designs to meet particular needs, whether they be for bespoke consumer goods, medical equipment, or automotive components. Moreover, businesses are able to address the specific demands of individual clients and cater to specialized markets because of this customization power.

Functional Prototypes

With SLA 3D printing, you can create functioning prototypes that closely match the finished product, in contrast to traditional prototyping techniques that frequently result in non-functional replicas. As a result, engineers may evaluate a part's functionality, fit, and performance early on in the design process. This reduces the chances of expensive mistakes and poor design.

Tooling and Moulding Applications

Businesses may drastically cut lead times and manufacturing costs by using SLA technology to create tools and mould inserts. High-quality final products are produced with exact geometry and flawless surface finishes provided by SLA-printed tools and moulds. Furthermore, producers may optimize tooling and moulds for better efficiency and performance by using fast design iterations.

Low-Volume Production

SLA technology is an affordable option for low-volume production, whether it is used to produce small quantities of customized parts or to meet the demands of specialized markets. Businesses can ensure production flexibility by using SLA-printed components instead of costly equipment and setup expenses that come with traditional manufacturing methods.

Sustainability

As SLA 3D printing uses less energy and generates less material waste, it also conforms to sustainable production principles. It creates parts layer by layer, utilizing just the material needed for the finished result, in contrast to subtractive manufacturing techniques that produce a large amount of waste during the machining and milling operations. Furthermore, SLA 3D printing can use biodegradable and recyclable polymers, which lessens its impact on the environment even further.

Bottom Line

For rapid prototyping as well as low-volume production, China 3D printing offers several benefits that help businesses in several industries. By leveraging the power of this technology, businesses can promote innovation, customize products, and streamline manufacturing processes.