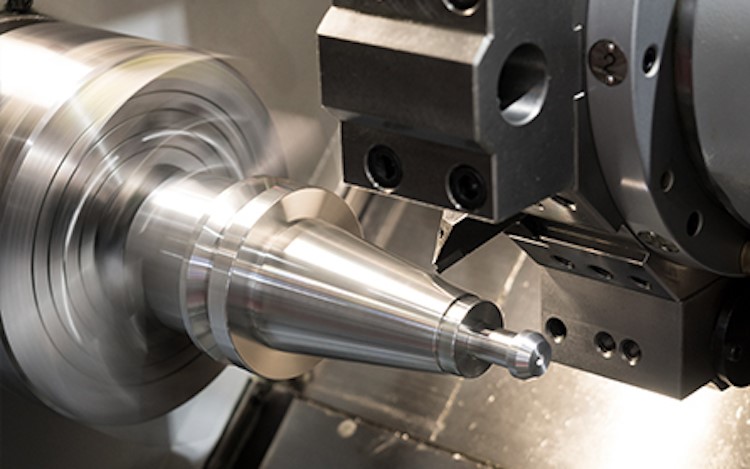

Computer

Numerical Control or CNC machining is a term widely used in manufacturing and

industrial applications. Not so old, but the introduction of CNC machining has brought

a revolution in the manufacturing process, taking the place of manual

control.

It’s

pre-programmed computer software that dictates the movement of the factory

tools and machinery. The use of CNC machines in the manufacturing units control

the range of complex machinery. Besides, the task of three-dimensional cutting

is easy to perform just in a single set of commands.

In

this post, we will discuss how the CNC machining process works and which

software is used for programming the commands.

Stages of the CNC machining process

Designing the CAD Model:

The

CNC machining service provider begins the process by creating a 2D vector or 3D

solid part CAD design. They use software and produce a model keeping the

necessary technical specification in mind. The design of the model depends on

the CNC machine tools and material used for manufacturing.

Converting the CAD file to the CNC Program:

Once

the design is made, the experts convert it into CNC compatible file format.

It’s because the CAD design will run only through a program. The program or the

converted file will be used in the digital programming code to control the CNC

machine. The codes will help in manipulating the tools and producing a

custom-designed part.

Preparing the CNC Machine:

Unlike

other pre-established machines, the CNC machine needs to be prepared before

operating. The experts prepare the machine by affixing the different parts and

pieces directly in the machine or similar work holding devices. Later, they

attach the required tools like drill bits to the machine components.

Executing the Machining operation:

After

all the above steps are done, the experts start executing the machining

operations. The CNC program prepared at the second stage is used as

instructions for the CNC machines. The commands dictate the tooling actions and

movements and guide the machine throughout the process. The direction helps in

the proper execution and production of the products.

Support Software used in CNC Machining Process

CAD or computer-aided design software- It helps in drafting

and designing 2D vector and 3D solid parts, as mentioned in the first stage.

The design helps in generating a CAD program in another stage.

CAM or computer-aided manufacturing software- It is used to extract

technical details from the CAD model designed using CAD software. The

information helps in generating a machine program for running a CNC

machine.

CAE or computer-aided engineering software- It is not used within

the process but plays a vital role other than that in the CNC machining

process. It helps the experts in pre-processing, analysing and post-processing

phases of the manufacturing. It’s like supportive software for in the

process.

So,

this was a brief or an overview of the CNC machining process and software used in

the same. To know more, connect with an experienced engineer working on this

particular process.